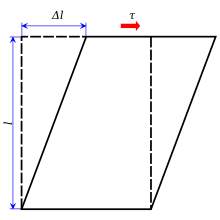

Shear stress

Normal stress, on the other hand, arises from the force vector component perpendicular to the material cross section on which it acts.

The formula to calculate average shear stress τ or force per unit area is:[1]

where μ is the dynamic viscosity, u is the flow velocity, and y is the distance from the wall.

It is used, for example, in the description of arterial blood flow, where there is evidence that it affects the atherogenic process.

[4][5] Shear stresses within a semi-monocoque structure may be calculated by idealizing the cross-section of the structure into a set of stringers (carrying only axial loads) and webs (carrying only shear flows).

Constructions in soil can also fail due to shear; e.g., the weight of an earth-filled dam or dike may cause the subsoil to collapse, like a small landslide.

The maximum shear stress created in a solid round bar subject to impact is given by the equation[6]

The shear stress is imparted onto the boundary as a result of this loss of velocity.

For a Newtonian fluid, the shear stress at a surface element parallel to a flat plate at the point y is given by

The fundamental aspect is that for a Newtonian fluid, the dynamic viscosity is independent of flow velocity (i.e., the shear stress constitutive law is linear), while for non-Newtonian flows this is not true, and one should allow for the modification

This no longer Newton's law but a generic tensorial identity: one can always find an expression of the viscosity as function of the flow velocity given any expression of the shear stress as function of the flow velocity.

If a sensor could directly measure the gradient of the velocity profile at the wall, then multiplying by the dynamic viscosity would yield the shear stress.

[8] The interference pattern generated by sending a beam of light through two parallel slits forms a network of linearly diverging fringes that seem to originate from the plane of the two slits (see double-slit experiment).

The signal can be processed, and from the fringe angle, the height and velocity of the particle can be extrapolated.

The measured value of the wall velocity gradient is independent of the fluid properties, and as a result does not require calibration.

advancements in the micro-optic fabrication technologies have made it possible to use integrated diffractive optical elements to fabricate diverging fringe shear stress sensors usable both in air and liquid.

[9] A further measurement technique is that of slender wall-mounted micro-pillars made of the flexible polymer polydimethylsiloxane, which bend in reaction to the applying drag forces in the vicinity of the wall.

The sensor thereby belongs to the indirect measurement principles relying on the relationship between near-wall velocity gradients and the local wall-shear stress.

[10][11] The electro-diffusional method measures the wall shear rate in the liquid phase from microelectrodes under limiting diffusion current conditions.

A potential difference between an anode of a broad surface (usually located far from the measuring area) and the small working electrode acting as a cathode leads to a fast redox reaction.

The ion disappearance occurs only on the microprobe active surface, causing the development of the diffusion boundary layer, in which the fast electro-diffusion reaction rate is controlled only by diffusion.

The resolution of the convective-diffusive equation in the near-wall region of the microelectrode lead to analytical solutions relying the characteristics length of the microprobes, the diffusional properties of the electrochemical solution, and the wall shear rate.