Newcomen atmospheric engine

The steam generated pressurized the container, but the inner pipe, immersed at the bottom by liquid, and lacking an airtight seal at top, remained at a lower pressure; expanding steam forced the water at the bottom of the container into and up the pipe to spurt out of a nozzle on top.

In 1606, the Spaniard, Jerónimo de Ayanz y Beaumont demonstrated and was granted a patent for a steam powered water pump.

In 1698 Thomas Savery patented a steam-powered pump he called the "Miner's Friend",[6] essentially identical to Somerset's design and almost certainly a direct copy.

Savery's invention cannot be strictly regarded as the first steam "engine" since it had no moving parts and could not transmit its power to any external device.

In Savery's pamphlet, he suggests setting the boiler and containers on a ledge in the mineshaft and even a series of two or more pumps for deeper levels.

Obviously these were inconvenient solutions and some sort of mechanical pump working at surface level – one that lifted the water directly instead of "sucking" it up – was desirable.

Louis Figuier in his monumental work[8] gives a full quotation of Denis Papin's paper published in 1690 in Acta eruditorum at Leipzig, entitled "Nouvelle méthode pour obtenir à bas prix des forces considérables" (A new method for cheaply obtaining considerable forces).

The fire was then removed, allowing the cylinder to cool, which condensed steam back into water, thus creating a vacuum beneath the piston.

Upon releasing the catch, the piston was sharply drawn down to the bottom of the cylinder by the pressure differential between the atmosphere and the created vacuum; enough force was thus generated to raise a 60 lb (27 kg) weight.

Unlike Savery's device, pumping was entirely mechanical, the work of the steam engine being to lift a weighted rod slung from the opposite extremity of the rocking beam.

A working replica can today be seen at the nearby Black Country Living Museum, which stands on another part of what was Lord Dudley's Conygree Park.

By the time of his death, Newcomen and others had installed over a hundred of his engines, not only in the West Country and the Midlands but also in north Wales, near Newcastle and in Cumbria.

Small numbers were built in other European countries, including in France, Belgium, Spain, and Hungary, also at Dannemora, Sweden.

Although based on simple principles, Newcomen's engine was rather complex and showed signs of incremental development, problems being empirically addressed as they arose.

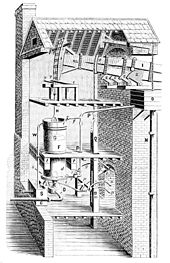

To start the engine, the regulator valve V was opened and steam admitted into the cylinder from the boiler, filling the space beneath the piston.

As the low pressure steam from the boiler flowed into the cylinder, the weight of the pump and gear returned the beam to its initial position whilst at the same time driving the water up from the mine.

Newcomen found that his first engine would stop working after a while, and eventually discovered that this was due to small amounts of air being admitted to the cylinder with the steam.

This was obtained by means of a plug tree which was a beam suspended vertically alongside the cylinder from a small arch head by crossed chains, its function being to open and close the valves automatically when the beam reached certain positions, by means of tappets and escapement mechanisms using weights.

Because of the very heavy steam demands, the engine had to be periodically stopped and restarted, but even this process was automated by means of a buoy rising and falling in a vertical stand pipe fixed to the boiler.

The buoy was attached to the scoggen, a weighted lever that worked a stop blocking the water injection valve shut until more steam had been raised.

In other industries, engine-pumping was less common, but Richard Arkwright used an engine to provide additional power for his cotton mill.

[20] Attempts were made to drive machinery by Newcomen engines, but these were unsuccessful, as the single power stroke produced a very jerky motion.

After the water vapor within was cooled enough to create the vacuum, the cylinder walls were cold enough to condense some of the steam as it was admitted during the next intake stroke.

Watt's vigorous defence of his patents resulted in the continued use of the Newcomen engine in an effort to avoid royalty payments.

[24] The only Newcomen-style engine still extant in its original location is at what is now the Elsecar Heritage Centre, near Barnsley in South Yorkshire.

[26] Another example, originally used at Farme Colliery is on display at Summerlee, Museum of Scottish Industrial Life; unusually it was used for winding rather than water pumping, and had been in operation for almost a century when examined in situ in 1902.

[27][28] In 1986, a full-scale operational replica of the 1712 Newcomen Steam Engine was completed at the Black Country Living Museum in Dudley.

Rods hang from the outer end of the beam and operate pumps at the bottom of the mine shaft which raise the water to the surface.

The steam in the cylinder is condensed by injecting cold water and the vacuum beneath the piston pulls the inner end of the beam down and causes the pump to move.

– Steam (pink), water (blue)

– Valves open (green), valves closed (red)