Parallel curve

[2][3][4] (In other geometric contexts, the term offset can also refer to translation.

[5]) Offset curves are important, for example, in numerically controlled machining, where they describe, for example, the shape of the cut made by a round cutting tool of a two-axis machine.

The shape of the cut is offset from the trajectory of the cutter by a constant distance in the direction normal to the cutter trajectory at every point.

[6] In the area of 2D computer graphics known as vector graphics, the (approximate) computation of parallel curves is involved in one of the fundamental drawing operations, called stroking, which is typically applied to polylines or polybeziers (themselves called paths) in that field.

[8] Increasing a solid volume by a (constant) distance offset is sometimes called dilation.

[8] Offset surfaces are important in numerically controlled machining, where they describe the shape of the cut made by a ball nose end mill of a three-axis machine.

[10] Other shapes of cutting bits can be modelled mathematically by general offset surfaces.

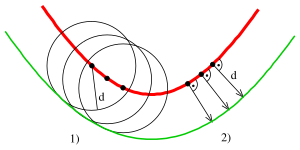

Only for the simple cases of lines and circles the parallel curves can be described easily.

For example: In general, presuming certain conditions, one can prove the existence of an oriented distance function

And:[17] When determining the cutting path of part with a sharp corner for machining, you must define the parallel (offset) curve to a given curve that has a discontinuous normal at the corner.

is discontinuous, meaning the one-sided limit of the normal from the left

at the sharp corner: The resulting definition of the parallel curve

Any desired level of accuracy is possible by repeatedly subdividing the curve, though better techniques require fewer subdivisions to attain the same level of accuracy.

A 1997 survey by Elber, Lee and Kim[19] is widely cited, though better techniques have been proposed more recently.

A modern technique based on curve fitting, with references and comparisons to other algorithms, as well as open source JavaScript source code, was published in a blog post[20] in September 2022.

Another efficient algorithm for offsetting is the level approach described by Kimmel and Bruckstein (1993).

[21] Offset surfaces are important in numerically controlled machining, where they describe the shape of the cut made by a ball nose end mill of a three-axis mill.

Note the similarity to the geometric properties of parallel curves.

[23] Note that the terminology for the higher-dimensional versions varies even more widely than in the planar case, e.g. other authors speak of parallel fibers, ribbons, and tubes.

[26] More recently Adobe Illustrator has added somewhat similar facility in version CS5, although the control points for the variable width are visually specified.

[27] In contexts where it's important to distinguish between constant and variable distance offsetting the acronyms CDO and VDO are sometimes used.

(this parameterization by normal exists for curves whose curvature is strictly positive or negative, and thus convex, smooth, and not straight).

General offset surfaces describe the shape of cuts made by a variety of cutting bits used by three-axis end mills in numerically controlled machining.

(this parameterization by normal exists for surfaces whose Gaussian curvature is strictly positive, and thus convex, smooth, and not flat).

Note the similarity to the geometric properties of general offset curves.

Assume you have a regular parametric representation of an n-dimensional surface,

Also assume you have a second n-dimensional surface that can be parameterized by its unit normal,

(this parameterization by normal exists for surfaces whose Gaussian curvature is strictly positive, and thus convex, smooth, and not flat).

Thus, the general offset surface shares the same tangent plane and normal with

The inverse of the shape operator holds these same values for the radii of curvature.