Otto cycle

The purpose of the Otto cycle is to study the production of net work from the system that can propel a vehicle and its occupants in the environment.

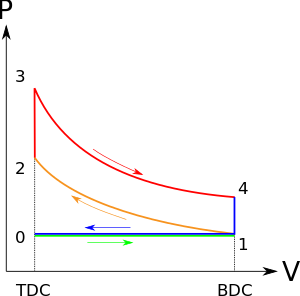

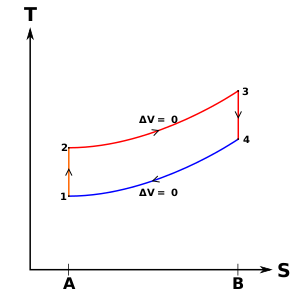

The processes are described by:[2] The Otto cycle consists of isentropic compression, heat addition at constant volume, isentropic expansion, and rejection of heat at constant volume.

In the case of a four-stroke Otto cycle, technically there are two additional processes: one for the exhaust of waste heat and combustion products at constant pressure (isobaric), and one for the intake of cool oxygen-rich air also at constant pressure; however, these are often omitted in a simplified analysis.

Even though those two processes are critical to the functioning of a real engine, wherein the details of heat transfer and combustion chemistry are relevant, for the simplified analysis of the thermodynamic cycle, it is more convenient to assume that all of the waste-heat is removed during a single volume change.

The four-stroke engine was first patented by Alphonse Beau de Rochas in 1861.

[3] Before, in about 1854–57, two Italians (Eugenio Barsanti and Felice Matteucci) invented an engine that was rumored to be very similar, but the patent was lost.

The compression and expansion processes induced on the gas by the movement of the piston are idealized as reversible, i.e., no useful work is lost through turbulence or friction and no heat is transferred to or from the gas during those two processes.

After the expansion is completed in the cylinder, the remaining heat is extracted and finally the gas is exhausted to the environment.

Mechanical work is produced during the expansion process and some of that used to compress the air mass of the next cycle.

A mass of air (working fluid) is drawn into the cylinder, from 0 to 1, at atmospheric pressure (constant pressure) through the open intake valve, while the exhaust valve is closed during this process.

Piston moves from crank end (BDC, bottom dead centre and maximum volume) to cylinder head end (TDC, top dead centre and minimum volume) as the working gas with initial state 1 is compressed isentropically to state point 2, through compression ratio (V1/V2).

During this instant, which is known as the ignition phase, the air/fuel mixture remains in a small volume at the top of the compression stroke.

Heat is added to the working fluid by the combustion of the injected fuel, with the volume essentially being held constant.

The increased high pressure exerts a force on the piston and pushes it towards the BDC.

The working gas pressure drops instantaneously from point 4 to point 1 during a constant volume process as heat is removed to an idealized external sink that is brought into contact with the cylinder head.

A simplification is made by assuming changes of the kinetic and potential energy that take place in the system (mass of gas) can be neglected and then applying the first law of thermodynamics (energy conservation) to the mass of gas as it changes state as characterized by the gas's temperature, pressure, and volume.

[2][page needed][6][page needed] During a complete cycle, the gas returns to its original state of temperature, pressure and volume, hence the net internal energy change of the system (gas) is zero.

Equation 1b: Each term of the equation can be expressed in terms of the internal energy of the gas at each point in the process: The energy balance Equation 1b becomes To illustrate the example we choose [dubious – discuss] some values to the points in the illustration: These values are arbitrarily but rationally [dubious – discuss] selected.

In the study of thermodynamic systems the extensive quantities such as energy, volume, or entropy (versus intensive quantities of temperature and pressure) are placed on a unit mass basis, and so too are the calculations, making those more general and therefore of more general use.

The specific heats are particularly useful for thermodynamic calculations involving the ideal gas model.

The foregoing discussion implies that it is more efficient to have a high compression ratio.

Usually this does not increase much because of the possibility of autoignition, or "knock", which places an upper limit on the compression ratio.

Autoignition occurs when the temperature of the fuel/air mixture becomes too high before it is ignited by the flame front.

The power produced by the Otto cycle is an energy developed per unit of time.

These results are the product of the values of the internal energy that were assumed for the four states of the system at the end each of the four strokes (two rotations).

Whose results would be higher than the actual engine as there are many simplifying assumptions made in the analysis that overlook inefficiencies.

A gas turbine can extract useful work energy from the exhaust stream and that can then be used to pressurize the intake air.

The intake air is typically cooled so as to reduce its volume as the work produced per stroke is a direct function of the amount of mass taken into the cylinder; denser air will produce more work per cycle.

Practically speaking the intake air mass temperature must also be reduced to prevent premature ignition in a petrol fueled engine; hence, an intercooler is used to remove some energy as heat and so reduce the intake temperature.

The application of a supercharger driven by the crankshaft does increase the power output (power density) but does not increase efficiency as it uses some of the net work produced by the engine to pressurize the intake air and fails to extract otherwise wasted energy associated with the flow of exhaust at high temperature and a pressure to the ambient.