Overhead camshaft engine

The other main advantage of OHC engines is that there is greater flexibility to optimise the size, location and shape of the intake and exhaust ports, since there are no pushrods that need to be avoided.

[1] This improves the gas flow through the engine, increasing power output and fuel efficiency.

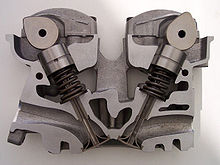

[a] Motion of the camshaft is usually transferred to the valves either directly (using a tappet) or indirectly via a rocker arm.

A further benefit is that the spark plug can be placed at the optimum location, which in turn improves combustion efficiency.

Another newer benefit of DOHC engine design is the ability to independently change/phase the timing between each camshaft and the crankshaft.

Many 21st century engines use a toothed timing belt made from rubber and kevlar to drive the camshaft.

[1][10] Timing belts are inexpensive, produce minimal noise and have no need for lubrication.

[24][25] The Crosley four cylinder was the last automotive engine to use the shaft tower design to drive the camshaft, from 1946 to 1952; the rights to the Crosley engine format were bought by a few different companies, including General Tire in 1952, followed by Fageol in 1955, Crofton in 1959, Homelite in 1961, and Fisher Pierce in 1966, after Crosley closed the automotive factory doors, and they continued to produce the same engine for several more years.

A camshaft drive using three sets of cranks and rods in parallel was used in the 1920–1923 Leyland Eight luxury car built in the United Kingdom.

The Isotta Fraschini Tipo KM— built in Italy from 1910–1914— was one of the first production cars to use an SOHC engine.

[33] During World War I, both the Allied and Central Powers; specifically those of the German Empire's Luftstreitkräfte air forces, sought to quickly apply the overhead camshaft technology of motor racing engines to military aircraft engines.

The DOHC Napier Lion W12 engine was built in Great Britain beginning in 1918.

Large aircraft engines— particularly air-cooled engines— experienced considerable thermal expansion, causing the height of the cylinder block to vary during operating conditions.

Other early SOHC automotive engines were the 1920–1923 Wolseley Ten, the 1928-1931 MG 18/80, the 1926–1935 Singer Junior and the 1928–1929 Alfa Romeo 6C Sport.

The 1946–1948 Crosley CC Four was arguably the first American mass-produced car to use an SOHC engine.

[38]: 121 Use of a DOHC configuration gradually increased after World War II, beginning with sports cars.