Paper engineering

[1] The field applies various principles in process engineering and unit operations to the manufacture of paper, chemicals, energy and related materials.

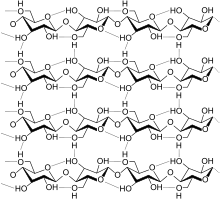

The following timeline shows some of the key steps in the development of the science of chemical and bioprocess engineering:[2] From a heritage perspective, the field encompasses the design and analysis of a wide variety of thermal, chemical and biochemical unit operations employed in the manufacture of pulp and paper, and addresses the preparation of its raw materials from trees or other natural resources via a pulping process, chemical and mechanical pretreatment of these recovered biopolymer (e.g. principally, although not solely, cellulose-based) fibers in a fluid suspension, the high-speed forming and initial dewatering of a non-woven web, the development of bulk sheet properties via control of energy and mass transfer operations, as well as post-treatment of the sheet with coating, calendering, and other chemical and mechanical processes.

Sulfate pulping can be performed on a wide range of tree varieties and results in the creation of a strong type of paper.

However, sulfate pulping is more widely used since the product is more durable and the chemicals used in the process can be recovered, thus resulting in minimal environmental pollution.

Today, the field of paper and bioprocess engineering is a diverse one, covering areas from biotechnology and nanotechnology to electricity generation.