Textile performance

Producers, distributors and retailers favor the expectations of the target market, and fashion their wares accordingly.

Aesthetics, durability, comfort and safety, appearance retention, care, environmental impact, and cost are the serviceability concepts employed in structuring the material.

[9][5] Aesthetics imply the appearance and attraction of textile products; it includes the color, pattern and texture of the material.

[10] Clothing provides comfort on a number of levels, including aesthetic, tactile, thermal, moisture, and pressure.

[11] Protection in textiles refers to a large application area where the performance (of functionality) is more central than aesthetic values.

[9] Care labelling for textile products takes into account the performance of each component as well as the manufacturing methods.

The halogenated flame retardants, PFC treated stain repellant, and triclosan or triclocarban or silver-containing antimicrobial fabrics certainly have a lot to do with the effluent and environment.

Fundamentally, each fiber and fabric has distinct properties, and they are chosen based on their suitability for fitness for purpose.

[46][47][48] Users have five basic criteria for performance, including appearance, comfort, durability, maintenance, and cost.

A few examples of different areas are: Tensile strength, bursting, sensorial comfort, thermal comfort, heat transfer, water repellency MVTR, air permeability, pilling, shrinkage, fading, lightfastness, drape and hand feel are a few performance parameters.

Fiber properties are fundamentally determined by their physical and chemical properties..[49] Specific finishing methods, functional finishes, fit, and product design could all be used to improve the overall performance of a textile product, allowing it to achieve higher performance levels.

[63] These include, inter alia: In terms of performance, wool has been advertised as a "miracle fabric"[38][64][65] as it naturally possesses a variety of functional properties, including stretch, warmth, water absorption, flame retardance, and the ability to wick away body moisture.

[79] Textile finishing is the process of converting the loomstate or raw goods into a useful product, which can be done mechanically or chemically.

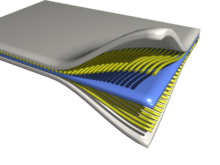

[81] This includes mechanical finishing and chemical applications which alter the composition of treated textiles (fiber, yarn or fabric.)

Nanotechnology unites a variety of scientific fields, such as material science, physics, chemistry, biology and engineering.

In textiles, surfaces with hydrophobic or hydrophilic properties are formed with the help of coatings and applied finishes.

Plasma is a highly reactive state that activates the substrate, and the oxidized surface of the plasma-treated textile improves dyeing while reducing environmental impacts.

[109] Light amplification by stimulated emission of radiation (laser) irradiation is used to modify the structural and surface properties of textiles, as well as to texturize them.

The test method evaluates the thermal resistance and water vapor permeability of fabrics, which bear on the garment's comfort.

[124][125] Kawabata evaluation system measures the mechanical properties of the textiles such as tensile strength, shear strength, surface friction and roughness, The Kawabata evaluation system predicts human responses and understands the perception of softness.

Additionally, it can be used to determine the transient heat transfer properties associated with the sensation of coolness generated when fabrics come into contact with the skin while being worn.