Pigging

Pigging systems are installed in industries handling products as diverse as lubricating oils, paints, chemicals, toiletries, cosmetics and foodstuffs.

Intelligent or "Smart pigs" are used to inspect pipelines to assess their condition and to prevent leaks, which can be hazardous or harmful to the environment.

Some early cleaning "pigs" were made from straw bales wrapped in barbed wire[4] while others used leather.

[7][8] A major advantage for multi-product pipelines of piggable systems is the potential of product savings.

Alternatively it is possible to clear out the entire line contents with the pig, either forwards to the receipt point, or backwards to the source tank.

Without the need for line flushing, pigging offers the additional advantage of much more rapid and reliable product changeover.

All of these problems can now be eliminated due to the very precise interface produced by modern pigging systems.

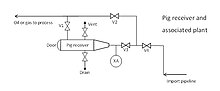

It shows two pig launcher/ receivers at the end of two 610-millimetre (24 in) diameter pipelines that carry gas under the River Thames, between East Tilbury in Essex and Shorne in Kent.

Common causes of such events are: All these causes are directly related to improper operation of the process valves and the closure door.

A common method of avoiding these kinds of incidents is to add valve interlocks,[15] which has been adopted by all global oil and gas operating companies.

There are four main uses for pigs: One of the most common and versatile is the foam pig which is cut or poured out of open cell polyurethane foam into the shape of a bullet and is driven through pipelines for many reasons such as to prove the inner diameter of, clean, de-water, or dry out the line.

Some have tungsten studs or abrasive wire mesh on the outside to abrade rust, scale, or paraffin wax deposits from the inside of the pipe.

There are also fully molded urethane pigs used for liquid removal, or batching several different products in one line.

These pigs use technologies such as magnetic flux leakage (MFL) and ultrasound to inspect the pipeline.

It demonstrated that a self-contained electronic instrument could traverse a pipeline while measuring and recording wall thickness.

[17] Testing was conducted by NETL DOE research lab at the Battelle West Jefferson's Pipeline Simulation Facility (PSF) near Columbus, Ohio.

[18] Modern, intelligent or "smart" pigs are highly sophisticated instruments that include electronics and sensors to collect various forms of data during their trip through the pipeline.

Surface pitting and corrosion, as well as cracks and weld defects in steel/ferrous pipelines are often detected using magnetic flux leakage (MFL) pigs.

[19] Caliper pigs can measure the roundness of the pipeline to determine areas of crushing or other deformations.

Some smart pigs use a combination of technologies, such as providing MFL and caliper functions in a single tool.

[21] The pig records this positional data so that the distance it moves along with any bends can be interpreted later to determine the exact path taken.

Location verification is often accomplished by surface instruments that record the pig's passage by either audible, magnetic, radio-transmission or other means.

In other words, the combined data reveals to the operator the location, type and size of each pipe defect.

By evaluating the rate of change of a particular defect over several years, proactive plans can be made to repair the pipeline before any leakage or environmental damage occurs.

A pig launcher was featured in the season 2 episode "Pipeline Fever" of the animated show Archer, wherein Sterling Archer and Lana Kane are tasked with going into a swamp and defending a pig launcher from radical environmentalist Joshua Gray.