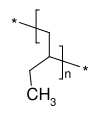

Polybutylene

Because of its specific properties it is mainly used in pressure piping, flexible packaging, water heaters, compounding and hot melt adhesives.

[dubious – discuss] Because of its crystalline structure and high molecular weight, PB-1 has good resistance to hydrostatic pressure, showing very low creep even at elevated temperatures.

[1] PB-1 generally resists chemicals such as detergents, oils, fats, acids, bases, alcohol, ketones, aliphatic hydrocarbons and hot polar solutions (including water).

[7] Additional features include excellent wet abrasion resistance, easy melt flowability (shear thinning), and good dispersion of fillers.

PB-1 piping systems are no longer being sold in North America (see "Class action lawsuits and removal from building code approved usage", below).

The overall market share in Europe and Asia is rather small but PB-1 piping systems have shown a steady growth in recent years.

In combination with its low melting point it can be employed in halogen-free flame retardant composites or as masterbatch carrier for thermo-sensitive pigments.

PB-1 disperses easily in other polyolefins, and at low concentration, acts as processing aid reducing torque and/or increasing throughput.

[11] The use of PB-1 foam as thermal insulation is of great advantage for district heating pipes, since the number of materials in the sandwich structure is reduced to one, facilitating its recycling.

[12] Other applications include domestic water heaters, electrical insulation, compression packaging, wire and cable, shoe soles, and polyolefin modification (thermal bonding, enhancing softness and flexibility of rigid compounds, increasing temperature resistance and compression set of soft compounds).

Problems with leaks and broken pipes led to a class action lawsuit, Cox v. Shell Oil, that was settled for $1 billion.

[15] Polybutylene water pipes are no longer accepted by the United States building codes and have been the subject[16] of class action lawsuits in both Canada and the U.S.[17][18] The National Plumbing Code of Canada 1995 listed polybutylene piping as acceptable for use with the exception of recirculation plumbing.

[20][21] There is evidence to suggest that the presence of chlorine and chloramine compounds in municipal water (often deliberately added to retard bacterial growth) will cause deterioration of the internal chemical structure of polybutylene piping and the associated acetal fittings.