Polyester

Polyesters are one of the most economically important classes of polymers, driven especially by PET, which is counted among the commodity plastics; in 2019 around 30.5 million metric tons were produced worldwide.

[13] Commodity plastics (such as polyethylene or polypropylene) have in this respect even greater limitations, but they are manufactured in great amounts at low cost.

Such polymers contain structures that impart high melting temperatures, resistance to oxidative degradation and stability to radiation and chemical reagents.

[14] The polymers' structures result also in poor processing characteristics, in particular a high melting point and low solubility.

The named properties are in particular based on a high percentage of aromatic carbons in the polymer backbone which produces a certain stiffness.

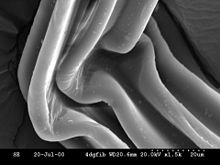

Fabrics woven or knitted from polyester thread or yarn are used extensively in apparel and home furnishings, from shirts and pants to jackets and hats, bed sheets, blankets, upholstered furniture and computer mouse mats.

Polyester fiber is used as cushioning and insulating material in pillows, comforters, stuffed animals and characters, and upholstery padding.

Thixotropic properties of spray-applicable polyesters make them ideal for use on open-grain timbers, as they can quickly fill wood grain, with a high-build film thickness per coat.

Abbreviations: A comparable small market segment (much less than 1 million tonnes/year) of polyester is used to produce engineering plastics and masterbatch.

This means the polymer melt is directly converted into the textile fibers or filaments without the common step of pelletizing.

Eastman Chemicals were the first to introduce the idea of closing the chain from PX to PET resin with their so-called INTEGREX process.

This is without counting all the companies involved in the supply industry, beginning with engineering and processing machines and ending with special additives, stabilizers and colors.

When melting points of the monomers are sufficiently low, a polyester can be formed via direct esterification while removing the reaction water via vacuum.

Direct bulk polyesterification at high temperatures (150 – 290 °C) is well-suited and used on the industrial scale for the production of aliphatic, unsaturated, and aromatic–aliphatic polyesters.

The reaction between diacyl chlorides and alcohols or phenolic compounds has been widely applied to polyester synthesis and has been subject of numerous reviews and book chapters.

Even though the acyl chloride based synthesis is also subject of reports in the patent literature, it is unlikely that the reaction is utilized on the production scale.

[23] In an interfacial acyl chloride-based reaction, the alcohol (generally in fact a phenol) is dissolved in the form of an alkoxide in an aqueous sodium hydroxide solution, the acyl chloride in an organic solvent immiscible with water such as dichloromethane, chlorobenzene or hexane, the reaction occurs at the interface under high-speed agitation near room temperature.

Since the molecular weight of the product obtained by a high-temperature synthesis can be seriously limited by side reactions, this problem is circumvented by the mild temperatures of interfacial polycondensation.

[21] The procedure is of little use in the production of polyesters based on aliphatic diols which have higher pKa values than phenols and therefore do not form alcoholate ions in aqueous solutions.

[4] The base catalysed reaction of an acyl chloride with an alcohol may also be carried out in one phase using tertiary amines (e. g. triethylamine, Et3N) or pyridine as acid acceptors: While acyl chloride-based polyesterifications proceed only very slowly at room temperature without a catalyst, the amine accelerates the reaction in several possible ways, although the mechanism is not fully understood.

[21] However, it is known that tertiary amines can cause side-reactions such as the formation of ketenes and ketene dimers.[24] In this variant of the HCl method, the carboxylic acid chloride is converted with the trimethyl silyl ether of the alcohol component and production of trimethyl silyl chloride is obtained Aliphatic polyesters can be assembled from lactones under very mild conditions, catalyzed anionically, cationically, metallorganically or enzyme-based.

[25][26] A number of catalytic methods for the copolymerization of epoxides with cyclic anhydrides have also recently been shown to provide a wide array of functionalized polyesters, both saturated and unsaturated.

The reaction proceeds, for example, via an intermediate N-acylimidazole which reacts with catalytically acting sodium alkoxide:[4] The use of activating agents for the production of high-melting aromatic polyesters and polyamides under mild conditions has been subject of intensive academic research since the 1980s, but the reactions have not gained commercial acceptance as similar results can be achieved with cheaper reactants.

The ratio between the polymer-forming ester group (-C(O)O-) and the condensation product water (H2O) against the acid-based (-C(O)OH) and alcohol-based (-OH) monomers is described by the equilibrium constant KC.

[20] The condensation product is therefore removed at reduced pressure and high temperatures (150–320 °C, depending on the monomers) to prevent the back reaction.

Carothers' research was incomplete and had not advanced to investigating the polyester formed from mixing ethylene glycol and terephthalic acid.

[30] Carothers' project was revived by British scientists Whinfield and Dickson, who patented polyethylene terephthalate (PET) or PETE in 1941.

The double bond of unsaturated polyesters reacts with a vinyl monomer, usually styrene, resulting in a 3-D cross-linked structure.

[33][34][35] Ahmed Shafik was a sexologist who won a Ig Nobel Prize on his research regarding how polyester can affect the fertility of rats,[36] dogs,[37] and men.

[41][42] The ester bond present in polyesters is susceptible to hydrolysis (acidic or basic conditions), methanolysis and glycolysis which makes this class of polymers suitable for chemical recycling.