Polyimide

[2] They found that 4-amino phthalic anhydride does not melt when heated but does release water upon the formation of a high molecular weight polyimide.

These materials tend to be insoluble and have high softening temperatures, arising from charge-transfer interactions between the planar subunits.

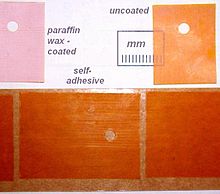

Thermosetting polyimides are known for thermal stability, good chemical resistance, excellent mechanical properties, and characteristic orange/yellow color.

Thermoset polymer matrix polyimides exhibit very low creep and high tensile strength.

Typical polyimide parts are not affected by commonly used solvents and oils – including hydrocarbons, esters, ethers, alcohols and freons.

Examples of polyimide films include Apical, Kapton, UPILEX, VTEC PI, Norton TH and Kaptrex.

[15] An additional use of polyimide resin is as an insulating and passivation[16] layer in the manufacture of Integrated circuits and MEMS chips.

[19] Multi-layer insulation used on spacecraft is usually made of polyimide coated with thin layers of aluminum, silver, gold, or germanium.

Polyimide powder can be used to produce parts and shapes by sintering technologies (hot compression molding, direct forming, and isostatic pressing).

Because of their high mechanical stability even at elevated temperatures they are used as bushings, bearings, sockets or constructive parts in demanding applications.

To improve tribological properties, compounds with solid lubricants like graphite, PTFE, or molybdenum sulfide are common.

Polyimide parts and shapes include P84 NT, VTEC PI, Meldin, Vespel, and Plavis.