Reversing gear

The most common form of reversing gear uses a lever to engage (known as a Johnson bar in the United States) mounted parallel to the direction of travel on the driver’s side of the cab.

A square pin is arranged to engage with notches cut in the plates and holds the lever (and valve gear) in the desired position when the trigger is released.

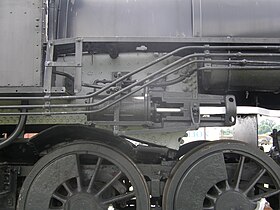

The Johnson bar is effectively part of the entire valve gear, being connected to the various linkages and arms in order to serve its function in adjusting them.

This will suddenly and violently throw the lever into the full cut-off position, carrying with it the real danger of injury to the driver, damage to the valve gear and triggering wheel slip in the locomotive.

On ascending gradients it was a matter of great skill to reduce the regulator opening by enough to safely unlatch the Johnson bar while maintaining sufficient steam pressure to the cylinders.

The dangers of the traditional Johnson bar (which grew as locomotive power, weight and operating steam pressures increased through the first half of the 20th century) led to it being banned in the USA by the Interstate Commerce Commission.

Compressed air from the brake reservoirs was applied to one side of the piston to reduce the effort required to lift the heavy expansion link, with gravity assisting in the opposite direction.

[1] With larger engines, the linkages involved in controlling cutoff and direction grew progressively heavier and there was a need for power assistance in adjusting them.

Typically, the operator worked a valve that admitted steam to one side or the other of a cylinder connected to the reversing mechanism until the indicator showed the intended position.

[2] Several engineers then tried them, including William Dean of the GWR and Vincent Raven of the North Eastern Railway, but they found them little to their liking, mainly because of maintenance difficulties: any oil leakage from the locking cylinder, either through the piston gland or the cock, allowed the mechanism to creep, or worse “nose-dive”, into full forward gear while running.

Later still the forward-looking Southern Railway engineer Oliver Bulleid fitted them to his famous Merchant Navy Class of locomotives, but they were mostly removed at rebuild.

Control is by a small three-way steam valve (“forward”, “stop”, “back”) and a separate indicator showing the position of the rod and thus the percentage of cutoff in use.