Pressurized water reactor

PWRs constitute the large majority of the world's nuclear power plants (with notable exceptions being the UK, Japan, India and Canada).

PWRs are operated in the United States, France, Russia, China, South Korea and several other countries.

Several hundred PWRs are used for marine propulsion in aircraft carriers, nuclear submarines and ice breakers.

[3] The United States Army Nuclear Power Program operated pressurized water reactors from 1954 to 1974.

Three Mile Island Nuclear Generating Station initially operated two pressurized water reactor plants, TMI-1 and TMI-2.

[4] The partial meltdown of TMI-2 in 1979 essentially ended the growth in new construction of nuclear power plants in the United States for two decades.

[9] Also in 2020, the Energy Impact Center introduced the OPEN100 project, which published open-source blueprints for the construction of a 100 MWelectric nuclear power plant with a PWR design.

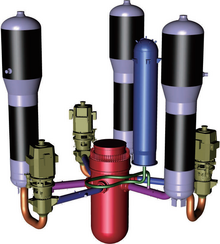

[11][12] The hot primary coolant is pumped into a heat exchanger called the steam generator, where it flows through several thousand small tubes.

[11][failed verification] Some common steam generator arrangements are u-tubes or single pass heat exchangers.

Therefore, if reactivity increases beyond normal, the reduced moderation of neutrons will cause the chain reaction to slow down, producing less heat.

This process is referred to as 'Self-Regulating', i.e. the hotter the coolant becomes, the less reactive the plant becomes, shutting itself down slightly to compensate and vice versa.

Thus there is less water to absorb thermal neutrons that have already been slowed by the graphite moderator, causing an increase in reactivity.

This is called the "positive scram effect" that is unique to the flawed RBMK control rods design.

These design flaws, in addition to operator errors that pushed the reactor to its limits, are generally seen as the causes of the Chernobyl disaster.

Depending on burnup, boric acid or another neutron poison will have to be added to emergency coolant to avoid a criticality accident.

The cylindrical pellets are then clad in a corrosion-resistant zirconium metal alloy Zircaloy which are backfilled with helium to aid heat conduction and detect leakages.

Boron and cadmium control rods are used to maintain primary system temperature at the desired point.

This decrease of power will eventually result in primary system temperature returning to its previous steady-state value.

Reactivity adjustment to maintain 100% power as the fuel is burned up in most commercial PWRs is normally achieved by varying the concentration of boric acid dissolved in the primary reactor coolant.

An entire control system involving high pressure pumps (usually called the charging and letdown system) is required to remove water from the high pressure primary loop and re-inject the water back in with differing concentrations of boric acid.

PWRs can passively scram the reactor in case offsite power is lost to immediately stop the primary nuclear reaction.

The control rods are held by electromagnets and fall by gravity when current is lost; full insertion safely shuts down the primary nuclear reaction.

Due to long experience with their operation they are the closest thing to mature technology that exists in nuclear energy.

Water is a nontoxic, transparent, chemically unreactive (by comparison with e.g. NaK) coolant that is liquid at room temperature which makes visual inspection and maintenance easier.

A typical PWR will exchange a quarter to a third of its fuel load every 18-24 months and have maintenance and inspection, that requires the reactor to be shut down, scheduled for this window.

This requires high strength piping and a heavy pressure vessel and hence increases construction costs.

Pressurized water reactors annually emit several hundred curies of tritium to the environment as part of normal operation.

Similarly process heat drawn from a PWR is not suitable for most industrial applications as those require temperatures in excess of 400 °C (752 °F).

During the Fukushima nuclear accident a hydrogen explosion damaging the containment building was a major concern, though the reactors at the plant were BWRs, which owing to the steam at the top of the pressure vessel by design carry a greater risk of this happening.

Some reactors contain catalytic recombiners which let the hydrogen react with ambient oxygen in a non-explosive fashion.