Produced water

It contains steam with dissolved solutes and gases, providing important information on the geological, chemical, and hydrological characteristics of geothermal systems.

[2] The U.S. Environmental Protection Agency (EPA) in 1987 and 1999 indicates that during drilling and operations, additives may be used to reduce solid deposition on equipment and casings.

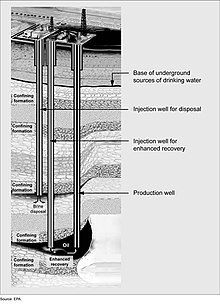

[13] The broad management options for re-use are direct injection, environmentally acceptable direct-use of untreated water, or treatment to a government-issued standard before disposal or supply to users.

In the United States, these standards are issued by the U.S. Environmental Protection Agency (EPA) for underground injection[14][15] and discharges to surface waters.

[17] Gravity separators, hydrocyclones, plate coalescers, dissolved gas flotation, and nut shell filters are some of the technologies used in treating wastes from produced water.

[19] In January 2020, Rolling Stone magazine published an extensive report about radioactivity content in produced water and its effects on workers and communities across the United States.

It was reported that brine sampled from a plant in Ohio was tested in a University of Pittsburgh laboratory and registered radium levels above 3,500 pCi/L.