Productivity-improving technologies

Cheap paper was a factor in the development of the movable type printing press, which led to a large increase in the number of books and titles published.

Bacon stated that the technologies that distinguished Europe of his day from the Middle Ages were paper and printing, gunpowder and the magnetic compass, known as the four great inventions, which had origins in China.

It had the immediate effect of dramatically reducing the energy required to produce pig iron, but reuse of heat was eventually applied to a variety of industries, particularly steam boilers, chemicals, petroleum refining and pulp and paper.

[7] Near the beginning of the Industrial Revolution came publication of the Encyclopédie, written by numerous contributors and edited by Denis Diderot and Jean le Rond d'Alembert (1751–72).

Most major innovations of the Second Industrial Revolution were based on the modern scientific understanding of chemistry, electromagnetic theory and thermodynamics and other principles known to the profession of engineering.

In the 1750s John Smeaton, the "father of civil engineering," significantly improved the efficiency of the water wheel by applying scientific principles, thereby adding badly needed power for the Industrial Revolution.

Until the late 19th century most coal and other minerals were mined with picks and shovels and crops were harvested and grain threshed using animal power or by hand.

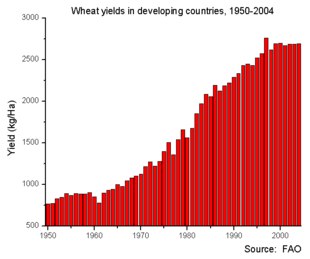

Output per man hour in growing wheat rose by a factor of about 10 from the end of World War II until about 1985, largely because of powered machinery, but also because of increased crop yields.

Multiple expansion (multi-stage) engines were developed in the 1870s and were efficient enough for the first time to allow ships to carry more freight than coal, leading to great increases in international trade.

This was demonstrated on an iron plate covered wooden tramway in 1805 at Croydon, U.K. “ A good horse on an ordinary turnpike road can draw two thousand pounds, or one ton.

A horse was then attached, which drew the wagons with ease, six miles in two hours, having stopped four times, in order to show he had the power of starting, as well as drawing his great load.”[33]Better lubrication, such as from petroleum oils, reduced friction losses in mills and factories.

[47] Around 1900 various types of conveyors (belt, slat, bucket, screw or auger), overhead cranes and industrial trucks began being used for handling materials and goods in various stages of production in factories.

Piggyback is the transporting of trailers or entire trucks on rail cars, which is a more fuel efficient means of shipping and saves loading, unloading and sorting labor.

Merchant capitalists or master craftsmen typically provided the materials and collected the work pieces, which were made into finished product in a central workshop.

[47][21][55] During the industrial revolution much production took place in workshops, which were typically located in the rear or upper level of the same building where the finished goods were sold.

Architectural standards cover numerous dimensions including stairs, doors, counter heights and other designs to make buildings safe, functional and in some cases allow a degree of interchangeability.

[75] MBE's employ professionals who use knowledge based techniques such areas as engineering, research and development, information technology, business administration, finance and accounting.

Using data for corn (maize) in the U.S., yields increased about 1.7 bushels per acre from the early 1940s until the first decade of the 21st century when concern was being expressed about reaching limits of photosynthesis.

[28] The size of blast furnaces grew greatly over the 20th century and innovations like additional heat recovery and pulverized coal, which displaced coke and increased energy efficiency.

Plastics can be inexpensively made into everyday items and have significantly lowered the cost of a variety of goods including packaging, containers, parts and household piping.

Seismic exploration, beginning in the 1920s, uses reflected sound waves to map subsurface geology to help locate potential oil reservoirs.

Call volume eventually grew so fast that it was feared the telephone system would consume all electricity production, prompting Bell Labs to begin research on the transistor.

[106] Communications satellites came into use in the 1960s and today carry a variety of information including credit card transaction data, radio, television and telephone calls.

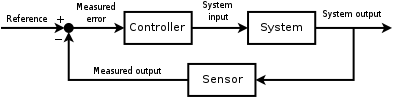

[109] The earliest applications of process control were mechanisms that adjusted the gap between mill stones for grinding grain and for keeping windmills facing into the wind.

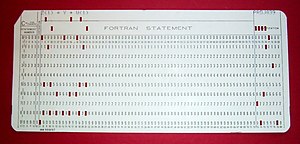

Tabulating machines were in a category called unit record equipment, through which the flow of punched cards was arranged in a program-like sequence to allow sophisticated data processing.

See: SQL Since the mid-1990s, interactive web pages have allowed users to access various servers over Internet to engage in e-commerce such as online shopping, paying bills, trading stocks, managing bank accounts and renewing auto registrations.

In a lengthy, costly, complicated, and intricate process of semiconductor device fabrication (SDFP, one of the most expensive industries as of 2022) various approaches were undertaken and many technologies were investigated since 1960s both by state (e.g.

As the integration of semiconductor and emergence of the VLSI devices grew over the years it became impossible to keep up with pace (see also Moore's law) without using specialized tools.

[116]: 47 Advances in photolithography technologies like krypton fluoride (KrF)-based excimer laser also helped to boost production rates at lower cost even at their own expensiveness.

[120][124][131] The computer and computer-like semiconductor devices used in automation are the most significant productivity-improving technologies developed in the final decades of the twentieth century; however, their contribution to overall productivity growth was disappointing.