Progressing cavity pump

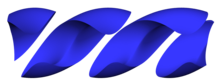

It transfers fluid by means of the progress, through the pump, of a sequence of small, fixed shape, discrete cavities, as its rotor is turned.

[2] The rotor takes a form similar to a corkscrew, and this, combined with the off-center rotary motion, leads to the alternative name: eccentric screw pump.

Different rotor shapes and rotor/stator pitch ratios exist, but are specialized in that they don't generally allow complete sealing, so reducing low speed pressure and flow rate linearity, but improving actual flow rates, for a given pump size, and/or the pump's solids handling ability.

To prevent this, pumps are often fitted with cut-off pressure switches, rupture discs (deliberately weak and easily replaced), or a bypass pipe that allows a variable amount of a fluid to return to the inlet.

At the points where the rotor touches the stator, the surfaces are generally traveling transversely, so small areas of sliding contact occur.

This can mean that more torque is required for starting, and if allowed to operate without fluid, called 'run dry', rapid deterioration of the stator can result.

Elastomer is used for the stator to simplify the creation of the complex internal shape, created by means of casting, which also improves the quality and longevity of the seals by progressively swelling due to absorption of water and/or other common constituents of pumped fluids.

The latter, having greater elastomer wall thickness at the peaks allows larger-sized solids to pass through because of its increased ability to distort under pressure.

The former have a constant elastomer wall thickness and therefore exceed in most other aspects such as pressure per stage, precision, heat transfer, wear, and weight.

In 1930, René Moineau, a pioneer of aviation, while inventing a compressor for jet engines, discovered that this principle could also work as a pumping system.