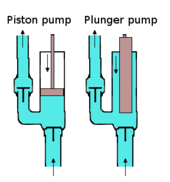

Piston pump

[1] Piston pumps can be used to move liquids or compress gases.

High pressure operation can be achieved without adversely affecting flow rate.

Piston pumps are often used in scenarios requiring high, consistent pressure and in water irrigation or delivery systems.

[4] Both types may be operated either by hand or by an engine.In a lift pump, the upstroke of the piston draws water, through a valve, into the lower part of the cylinder.

On the downstroke, water passes through valves set in the piston into the upper part of the cylinder.

On the next upstroke, water is discharged from the upper part of the cylinder via a spout.

This type of pump is limited by the height of water that can be supported by air pressure against a vacuum.

In a force pump, the upstroke of the piston draws water, through an inlet valve, into the cylinder.

Piston pumps may be classified as either single-acting and single-effect (the fluid is pumped by a single face of the piston, and the active stroke is in only one direction) or double-acting and double-effect (the fluid is pumped by both faces of the piston, and the strokes in both directions are active).The calculation of a piston pump's theoretical delivery rate is relatively simple.

In a single acting pump, only one side of the piston is in contact with the fluid.

In a double acting pump, both sides of the piston are in contact with the fluid.

However, this equation fails to take into consideration the volume taken up by the piston rod.

The following diagram shows the relation between the angle of the crankshaft and the delivery rate of a single-acting and double-acting pump.

These fluctuations in pressure and delivery can cause undesired effects such as water hammer and thus are generally mitigated by the installation of an air-filled accumulator.

As a result the actual delivery rate is often smaller and can be found by the following equation: