Coal dust

However, coal dust is hazardous to workers if it is suspended in air outside the controlled environment of grinding and combustion equipment.

Pulverized coal is a significant dust explosion hazard, as large quantities are suspended in air for transfer from the mill to the power plant.

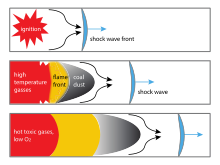

Such accidents were usually initiated by firedamp ignitions, the shock wave of which raised coal dust from the floor of the mine galleries to make an explosive mixture.

The problem was investigated by Michael Faraday and Charles Lyell at the colliery at Haswell County Durham of 1844, but their conclusions were ignored at the time.

Government agencies in the United States have set exposure limit guidelines for coal dust inhalation.

With the presence of coal dust within multiple industries, such as: mining, energy generation, and concrete production, different approaches are necessary.

[2] To prevent explosions, it is best to promote and execute good hygiene practices in the workplace by controlling both the coal dust and any possible ignition sources.

[2] Some ignition sources that may need to be controlled or used carefully around coal dust includes heavy machinery, electrical components, and open flames or sparks.