Industrial radiography

The examination can be performed in static 2D (named radiography), in real time 2D (fluoroscopy), or in 3D after image reconstruction (computed tomography or CT).

Radiography started in 1895 with the discovery of X-rays (later also called Röntgen rays after the man who first described their properties in detail), a type of electromagnetic radiation.

The result is a two-dimensional projection of the part onto the film, producing a latent image of varying densities according to the amount of radiation reaching each area.

After this visual examination, the operator will have a clear idea of the possibilities of access to the two faces of the weld, which is important both for the setting up of the equipment and for the choice of the most appropriate technique.

Without overlooking the negatives of radiographic inspection, radiography does hold many significant benefits over ultrasonics, particularly insomuch that as a 'picture' is produced keeping a semi permanent record for the life cycle of the film, more accurate identification of the defect can be made, and by more interpreters.

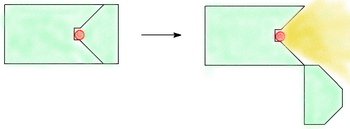

This exposure is created when the radiographer places the source of radiation at the center of a sphere, cone, or cylinder (including tanks, vessels, and piping).

It also has the advantage of taking less time than other arrangements since the source must only penetrate the total wall thickness (WT) once and must only travel the radius of the inspection item, not its full diameter.

The major disadvantage of the panoramic is that it may be impractical to reach the center of the item (enclosed pipe) or the source may be too weak to perform in this arrangement (large vessels or tanks).

The fourth is reserved for flat objects, such as plate metal, and is also radiographed without the source coming in direct contact with the item.

This exposure arrangement takes more time than a panoramic, as the source must first penetrate the WT twice and travel the entire outside diameter of the pipe or vessel to reach the film on the opposite side.

The American artist Kathleen Gilje has painted copies of Artemisia Gentileschi's Susanna and the Elders and Gustave Courbet's Woman with a Parrot.

Gilje's paintings are exhibited with radiographs that show the underpaintings, simulating the study of pentimentos and providing a comment on the old masters' work.

The three most important inelastic interactions with X-rays at those energy levels are the photoelectric effect, compton scattering and pair production.

They work in a similar way to produce X-rays, by electron collisions on a metal anode, the difference is that they use a much more complex method to accelerate them.

[10] These isotopes emit radiation in a discrete set of energies, depending on the decay mechanism happening in the atomic nucleus.

They always need to be enclosed in a shielded container and because they are still radioactive after their normal life cycle, their ownership often requires a license and they are usually tracked by a governmental body.

Another design for a shutter is where the source is placed in a metal wheel, which can turn inside the camera to move between the expose and storage positions.

Modern projector designs use a cable drive mechanism to move the source along a hollow guide tube to the exposure location.

The International Atomic Energy Agency has published a report describing the best practices in order to lower the amount of radiation dose the workers are exposed to.

National radiation safety authorities usually regulate the design, commissioning, maintenance and inspection of Industrial Radiography installations.

[21] Industrial radiographers are in many locations required by governing authorities to use certain types of safety equipment and to work in pairs.

Depending on location industrial radiographers may have been required to obtain permits, licenses and/or undertake special training.

When properly calibrated, activated, and worn on the radiographer's person, it will emit an alarm when the meter measures a radiation level in excess of a preset threshold.

Without the survey meter, the radiation received may be just below the threshold of the rate alarm, and it may be several hours before the radiographer checks the dosimeter, and up to a month or more before the film badge is developed to detect a low intensity overexposure.

Without the dosimeter, the radiographer may be unaware of an overexposure, or even a radiation burn, which may take weeks to result in noticeable injury.

There are three ways a radiographer will ensure they are not exposed to higher than required levels of radiation: time, distance, shielding.

The further a person is from a radioactive source the lower the level of radiation they receive, this is largely due to the inverse square law.

The most commonly used shielding materials in use are sand, lead (sheets or shot), steel, spent (non-radioactive uranium) tungsten and in suitable situations water.

Fatigue, carelessness and lack of proper training are the three most common factors attributed to industrial radiography accidents.

Many of the "lost source" accidents commented on by the International Atomic Energy Agency involve radiography equipment.