Reflux

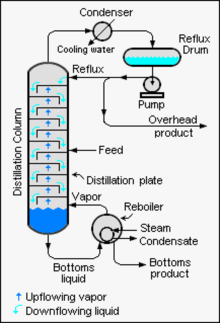

Conversely, for a given desired separation, the more reflux is provided, the fewer theoretical plates are required.

This vessel is connected to a water-cooled condenser, which is typically open to the atmosphere at the top.

The purpose is to thermally accelerate the reaction by conducting it at an elevated, controlled temperature (i.e. the solvent's boiling point) and ambient pressure without losing large quantities of the mixture.

The liquid feed mixture to be distilled is placed into the round-bottomed flask along with a few anti-bumping granules, and the fractionating column is fitted into the top.

The separation can be enhanced with the addition of more trays (to a practical limitation of heat, flow, etc.).

For high quality neutral spirits (such as vodka), or post distillation flavored spirits (gin, absinthe), a process of multiple distillations or charcoal filtering may be applied to obtain a product lacking in any suggestion of its original source material for fermentation.

Typical results can increase production as high as 50% over the basic worm type condenser.