Reverberatory furnace

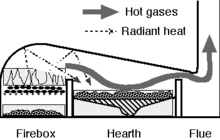

A reverberatory furnace is at a disadvantage from the standpoint of efficiency compared to a blast furnace due to the separation of the burning fuel and the subject material, and it is necessary to effectively utilize both reflected radiant heat and direct contact with the exhaust gases (convection) to maximize heat transfer.

The brightly visible flames, due to the substantial volatile component, give more radiant heat transfer than anthracite coal or charcoal.

Sir Clement Clerke and his son Talbot built cupolas or reverberatory furnaces in the Avon Gorge below Bristol in about 1678.

[citation needed] Reverberatory furnaces are widely used to melt secondary aluminium scrap for eventual use by die-casting industries.

[4] The simplest reverberatory furnace is nothing more than a steel box lined with alumina refractory brick with a flue at one end and a vertically lifting door at the other.

Conventional oil or gas burners are placed usually on either side of the furnace to heat the brick and the eventual bath of molten metal is then poured into a casting machine to produce ingots.