Rifled breech loader

At the time of development of the first modern breechloaders in the mid-19th century, gunpowder propellant charges for artillery were typically loaded in cloth bags, which combusted totally on firing.

The very first cannons of the Middle Ages were breech loaded, with gunpowder and shot contained in pots dropped at the back of the barrel, but the poor seals made them dangerous, and they wore quickly and could not be scaled to larger weapons.

In 1837, Martin von Wahrendorff patented a design for a breech-loader with a cylindrical breech plug secured by a horizontal wedge; it was adopted by Sweden in 1854.

Armstrong screw-breech guns were initially adopted by the British Army and Royal Navy, but concerns about limited armour penetration of the shells due to limited maximum velocity, safety concerns with the breech blocks blowing out of guns, and higher skill levels demanded of gunners led the British Government to revert to rifled muzzle-loaders from 1865 to 1880, when Britain finally deployed reliable screw breech mechanisms.

However, the British Army and Navy preferred to revert to muzzle-loaders until larger high-powered breech-loaders with secure obturation systems that were relatively simple to operate were developed.

American engineer Lewis Wells Broadwell who worked as sales agent for the Gatling Gun Company in Europe replaced a papier-mache obturating cup in bag-loaded RBLs with a metallic gas ring and patented his invention in 1861, later perfecting it in 1864 and 1866; most countries paid royalties to Broadwell for the design, but in Germany the Krupp company stole it and used it for free.

[3] In the meantime the French persevered with trying to develop breechloaders which combined faster loading than muzzle-loaders, high power, safety and solved the problem of obturation.

The Lahitolle 95 mm cannon of 1875 with an interrupted screw breech met the first three requirements to a great extent and partially solved the obturation problem.

Finally the de Bange system introduced in 1877 solved the obturation problem with an asbestos pad impregnated with grease which expanded and sealed the breech on firing.

Britain adopted the de Bange breech when it returned to breechloaders in the early 1880s after some initial experiments with the inferior "Armstrong cup" obturation system.

The sliding block, in both horizontal and vertical forms, and metal cartridge case continued to be the preferred German breech system until after World War II (e.g. 7.5 cm Pak 40), and is still used by some modern artillery.

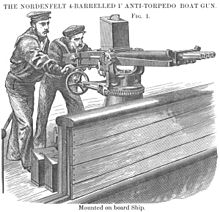

It was superseded for anti-torpedo boat defence in the mid-1880s by the new generation of Hotchkiss and Nordenfelt "QF" guns of 47-mm and 57-mm calibre firing exploding "common pointed" shells weighing 3–6 lb (1.4–2.7 kg).

The gun was ideal for defending against small fast vessels such as torpedo boats and was immediately adopted by the RN as the "Ordnance QF 3 pounder Hotchkiss".