Rifling

Rifling is the term for helical grooves machined into the internal surface of a firearms's barrel for imparting a spin to a projectile to improve its aerodynamic stability and accuracy.

A shorter distance/lower ratio indicates a faster twist, generating a higher spin rate (and greater projectile stability).

The combination of length, weight, and shape of a projectile determines the twist rate needed to gyroscopically stabilize it: barrels intended for short, large-diameter projectiles such as spherical lead balls require a very low twist rate, such as 1 turn in 48 inches (122 cm).

Muskets are smoothbore, large caliber weapons using ball-shaped ammunition fired at relatively low velocity.

Due to the high cost, great difficulty of precision manufacturing, and the need to load readily and speedily from the muzzle, musket balls were generally a loose fit in the barrels.

This was countered when accuracy was more important, for example when hunting, by using a tighter-fitting combination of a closer-to-bore-sized ball and a patch.

[5] Some of the earliest recorded European attempts of spiral-grooved musket barrels were of Gaspard Kollner, a gunsmith of Vienna in 1498 and Augustus Kotter of Nuremberg in 1520.

[6][7][8] There may have been attempts even earlier than this, as the main inspiration of rifled firearms came from archers and crossbowmen who realized that their projectiles flew far faster and more accurately when they imparted rotation through twisted fletchings.

Due to the laborious and expensive manufacturing process involved, early rifled firearms were primarily used by wealthy recreational hunters, who did not need to fire their weapons many times in rapid succession and appreciated the increased accuracy.

Rifled firearms were not popular with military users since they were difficult to clean, and loading projectiles presented numerous challenges.

If the bullet was of sufficient diameter to take up the rifling, a large mallet was required to force it down the bore.

The first practical military weapons using rifling with black powder were breech loaders such as the Queen Anne pistol.

For best performance, the barrel should have a twist rate sufficient to spin stabilize any bullet that it would reasonably be expected to fire, but not significantly more.

The M16A2 rifle, which is designed to fire the 5.56×45mm NATO SS109 ball and L110 tracer bullets, has a 1 in 7-inch (18 cm) or 32 calibers twist.

This method does not give an easy or straightforward understanding of whether a twist rate is relatively slow or fast when bores of different diameters are compared.

The second method describes the 'rifled travel' required to complete one full projectile revolution in calibers or bore diameters:

In 1879, George Greenhill, a professor of mathematics at the Royal Military Academy (RMA) at Woolwich, London, UK[9] developed a rule of thumb for calculating the optimal twist rate for lead-core bullets.

[15] For example, an M4 Carbine with a twist rate of 1 in 7 inches (177.8 mm) and a muzzle velocity of 3,050 feet per second (930 m/s) will give the bullet a spin of 930 m/s / 0.1778 m = 5.2 kHz (314,000 rpm).

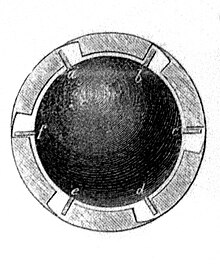

Typically the rifled barrel contains one or more grooves that run down its length, giving it a cross-section resembling an internal gear, though it can also take the shape of a polygon, usually with rounded corners.

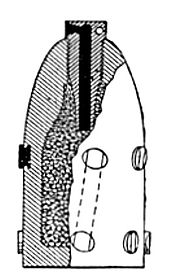

Freebore may allow more effective use of propellants by reducing the initial pressure peak during the minimum volume phase of internal ballistics before the bullet starts moving down the barrel.

The blades were in slots in a wooden dowel which were gradually packed out with slips of paper until the required depth was obtained.

The process was finished off by casting a slug of molten lead into the barrel, withdrawing it and using it with a paste of emery and oil to smooth the bore.

Typically rifling is a constant rate down the barrel, usually measured by the length of travel required to produce a single turn.

Minimizing freebore improves accuracy by decreasing the chance that a projectile will distort before entering the rifling.

Polygonal rifling is currently seen on pistols from CZ, Heckler & Koch, Glock, Tanfoglio, and the Kahr Arms (P series only), as well as the Desert Eagle.

For field artillery pieces, the extended range, full bore (ERFB) concept developed in early 1970s by Dennis Hyatt Jenkins and Luis Palacio[23] of Gerald Bull's Space Research Corporation for the GC-45 howitzer replaces the bourrelet with small nubs, which both tightly fit into lands of the barrel.

A gain-twist or progressive rifling begins with a slow twist rate that gradually increases down the bore, resulting in very little initial change in the projectile's angular momentum during the first few inches of bullet travel after it enters the throat.

After engaging the rifling at the throat, the bullet is progressively subjected to accelerated angular momentum as it is propelled down the barrel.

The theoretical advantage is that by gradually increasing the spin rate, torque is imparted along a much longer bore length, allowing thermomechanical stress to be spread over a larger area rather than being focused predominantly at the throat, which typically wears out much faster than other parts of the barrel.

It is seldom used in commercially available products, though notably on the Smith & Wesson Model 460 (X-treme Velocity Revolver).