Riveting machine

Orbital riveting machines are used in a wide range of applications including brake linings for commercial vehicles, aircraft, and locomotives, textile and leather goods, metal brackets, window and door furniture, latches and even mobile phones.

Pneumatic orbital riveting machines typically provide downward force in the 1,000–7,500 lb (450–3,400 kg) range.

Hydraulic orbital riveting machines typically provide downward force in the 6,000–50,000 lb (2,700–22,700 kg) range.

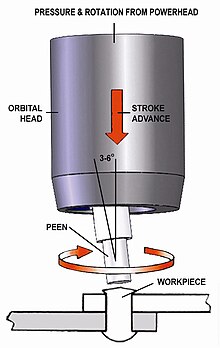

In most cases however, where high-quality joints are demanded, the radial riveting technology is the appropriate procedure due to the low cycle time, the little force needed and the high quality results obtained.

Excellent surface structure of the closing head: With the Radial riveting process, the tool itself does not rotate.

These machines take the automation one step farther by clamping the material and drilling or countersinking the hole in addition to riveting.

They are commonly used in the aerospace industry because of the large number of holes and rivets required to assemble the aircraft skin.

[1] Riveting machines are used in a wide range of applications including brake linings for commercial vehicles, aircraft, and locomotives, textile and leather goods, metal brackets, window and door furniture, latches and even mobile phones.