Robert Poole (industrialist)

For his workforce he hired members of what would become the first generation of modern metalworkers (machinists, molders, patternmakers, and boilermakers)—an emerging trade whose numbers would swell to 250,000 nationally by the end of the 19th century.

[3] Poole’s company made the columns that encircle the base of the dome of the United States Capitol in Washington, D.C., engines that powered Union gunships during the Civil War, hydraulic pumps that dredged the Potomac River (creating park land for national monuments), and complex devices (known as carriages) that controlled the raising and lowering of long-range guns for the defense of the U.S. coastline for the federal government.

For industry, the Poole company produced metal-based turbines and millwork that powered new and expanding manufacturers of flour, fertilizer, paper, and textiles—industries central to a growing economy.

Municipalities bought Poole-made steam fire engines, horsecars that ran on rails, and mechanisms that drove urban cable cars—new services for the nation's burgeoning cities.

As an only child Poole lived in a one-story dwelling on an eight-acre farm outside the village of Gulladuff, 40 miles (64 km) northwest of Belfast, in what would become Northern Ireland.

Starting at the age of 15 Poole apprenticed with a blacksmith, with machinists in textile mills, and with the engineer Ross Winans in the shops of the fledgling Baltimore and Ohio Railroad.

[10] In 1853, after a fire in their foundry and machine shop, and a city-wide strike of metalworkers, the partners moved their operations from Baltimore to what was then the village of Woodberry,[11] a few miles north of the city.

Responsible for enlarging and modernizing the overcrowded building, the architect of the project, Thomas U. Walter made architectural history when he selected iron instead of marble for the thirty-six columns (known as a peristyle) that surround the base of the dramatic new dome he designed.

[16] Over his lifetime, Poole was granted eleven patents—one for improving the durability of wheels on railroad rolling stock and another for a device that accelerated the heating of water before it entered a boiler.

George Babcock and Stephen Wilcox, Jr. of Providence licensed the Poole company to manufacture their patented safety boiler.

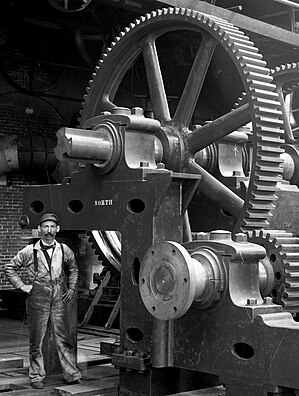

[19] Robert Poole and Englishman John Walker collaborated on the manufacture and use of semi-automated, gear-molding machinery (an advance over cast and machine-cut gears) that, reportedly, sped production and improved their quality.

[29] On 7 November 1841 Robert Poole and Ann Simpson (1818–1891) were married in the Emory Methodist Episcopal Church in her home town of Ellicott Mills, Maryland.