Robert de Wendel

After being devastated by two fires, the building was renovated in 1867, and the west wing was transformed into a home for Robert de Wendel.

[5][6] Robert de Wendel's wife appealed to French prime minister Adolphe Thiers in Paris.

[6] He reassured parliament that "There will always be iron throughout France that is as good as in Sweden, and the prosperity of the east's metallurgic industry is a complete illusion that will not last forever.

[4] Gargan and Robert de Wendel chose French citizenship, which meant they could not stay in occupied Lorraine since they were of the age of military service.

A group of German and Austrian banks offered to buy a large portion of the company, but the family rejected it on sentimental grounds.

[4] In 1879 Henri de Wendel obtained a sub-license for the Gilchrist Thomas process for making steel from the German licensee for 1 million reichsmarks, payable over ten years.

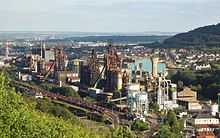

[4][a] The firm also acquired a new iron ore mine and ironworks at Jœuf, just over the border in France, upstream from Moyeuvre on the Orne River.

[4] Eugène Schneider thought it unwise to make a heavy investment in a steelworks so close to the German border, so allowed the Wendels to take the majority stake in the new company.

The first blast furnaces was fired up in Jœuf in 1882 and production of steel began in 1883, managed by Théodore de Gargan.

[12] In 1880 Robert de Wendel, master of forges in Hayange, Moyeuvre, Stiring-Wendel and Jœuf, ceded the license for the Gilchrist Thomas process for use by the Longwy steelworks.

[12] The Thomas process made very large scale metallurgy practical, even with the low-grade minette iron ores of Lorraine.

[14] After Baron René Reille's death in 1898 Robert de Wendel was elected president of the Comité des forges after some resistance.