Roller screw

Roller screw mechanisms are commonly incorporated into motion/positioning systems in a variety of industries such as manufacturing and aerospace.

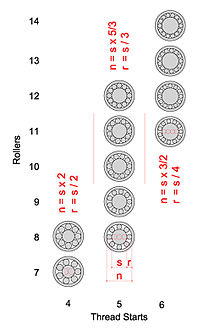

Providing more bearing points than ball screws within a given volume, roller screws can be more compact for a given load capacity while providing similar efficiency (75%-90%) at low-to-moderate speeds, and maintain relatively high efficiency at high speeds.

The rollers spin in contact with, and serve as low-friction transmission elements between, screw and nut.

Carl Bruno Strandgren developed some of the earliest effective forms of roller screws and applied for a patent in Nice, France in February 1942.

The first commercial roller screw was designed and manufactured under his supervision in 1949 and was mounted on a narrow-gauge locomotive which operated in a northern France coal mine.

The four commercially available types of roller screw are standard, inverted, recirculating, and bearing ring.

Differential roller screws, typically variants of the standard and recirculating types, are also commercially available.

[4] Now that the core patents have expired, an open source roller screw was developed in OpenSCAD to be 3-D printed for food processing applications.

[5] The planetary roller screw can be fabricated in dishwasher-safe polyethylene terephthalate glycol (PETG) on any desktop 3-D printer.

The rollers move axially within the nut, which is elongated to accommodate the full extent of screw shaft travel.

A recirculating roller screw can provide a very high degree of positional accuracy by using minimal thread leads.

In 2006, Charles C. Cornelius and Shawn P. Lawlor received a patent for a cageless recirculating roller screw system.

[7] In 1986 Oliver Saari was awarded a patent for a bearing ring roller screw, commonly referred to by its trademark, Spiracon.

The spacer rings have equidistant holes that act as rotary bearings for the smooth pivot ends (studs) of the rollers.

The rollers act as the “threads” of the nut assembly, causing axial movement of the rotating screw due to their orbital restraint.

Timothy A. Erhart was awarded a US patent in 1996 for a linear actuator effectively incorporating an inverted bearing ring roller screw.

The bearing ring is elongated and internally threaded for the length of screw shaft travel.