Roots blower

Unlike the basic illustration, most modern Roots-type superchargers incorporate three-lobe or four-lobe rotors; this allows the lobes to have a slight twist[clarification needed] along the rotor axes, which reduces pulsing in the input and output (this is impractical with two lobes, as even a slight twist could open up a free path through the supercharger at certain angles)[citation needed].

Of the three basic supercharger types, the Roots design historically possessed the worst thermal efficiency, especially at high pressure ratios.

[citation needed] With a Roots-type supercharger, one method successfully employed is the addition of a thin heat exchanger placed between the blower and the engine.

Current competition dragsters use aftermarket GMC variants similar in design to the 71 series, but with the rotor and case length increased for added capacity; hot rodders also use reproduction 6-71s.

Roots blowers are typically used in applications where a large volume of air must be moved across a relatively small pressure differential.

One very common industrial application is in pneumatic conveying systems,[4] the blower delivering a high volume of air for the movement of bulk solids through pipes.

Some civil defense sirens used Roots blowers to pump air to the rotor (chopper) so as to drastically increase its sound output through all pitch ranges.

Roots blowers were used for cabin pressurisation in aircraft, initially being investigated immediately before WW2 (using the Marshall supercharger) and made by companies such as Sir George Godfrey and Partners who were still shipping increasing numbers into the 1960s, they were later superseded by air bleeds from jet engine compression stages.

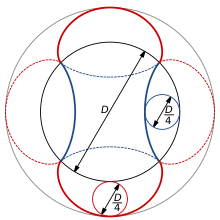

[5] The simplest form of a Roots blower has cycloidal rotors, constructed of alternating tangential sections of hypocycloidal and epicycloidal curves.

Because a Roots-type blower pumps air in discrete pulses (unlike a screw compressor), pulsation noise and turbulence may be transmitted downstream.

In most cases, as the map shows, this will move it into higher efficiency areas on the left as the smaller blower likely will have been running fast on the right of the chart.

That functions as a kind of liquid aftercooler system and goes a long way to negating the inefficiency of the Roots design in that application.

Rotary lobe blowers, commonly called boosters in high vacuum application, are not used as a stand-alone pump.

The term "blower" is commonly used to define a device placed on engines with a functional need for additional airflow using a direct mechanical link as its energy source.

Conversely, a turbocharger, using exhaust compression to spin its turbine, and not a direct mechanical link, is not generally regarded as a "blower" but simply a "turbo".

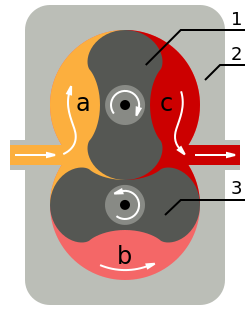

- Rotary vane 1

- Pump body

- Rotary vane 2

- Intake

- Pumping

- Output