Saturn V dynamic test vehicle

Though SA-500D never flew, it was instrumental in the development of the Saturn V rocket which propelled the first men to the Moon as part of the Apollo program.

Built under the direction of Dr. Wernher von Braun, it served as the test vehicle for all of the Saturn support facilities at MSFC.

[3][5][6][7][8][9][10] Before a Saturn V could be launched, engineers needed to verify that their design had accounted for everything the rocket would encounter on its journey, from assembly to the launchpad and from Earth to the Moon.

[12] Other pre-flight configurations were: The vehicle designated SA-500D did not include an Apollo spacecraft, but boilerplate parts were used during testing to verify the entire system.

[17] The third stage, S-IVB provided the final push to orbit and the trans-lunar injection burn to set the Apollo spacecraft on a course to the Moon.

Boilerplate size, shape, mass and center of gravity were the same, but it was not necessary for the entire Apollo spacecraft to be complete to commence dynamic testing.

With ceremony and dignitaries for the first Douglas-built S-IVB stage, it set out by barge December 8, 1964, and made its way to New Orleans via the Panama Canal, the Mississippi, Ohio, and Tennessee Rivers to MSFC, where it arrived on January 4, 1965.

The same day, MSFC took delivery of the first stage of the Saturn IB for dynamic and facilities checkout testing, S-IB-D/F.

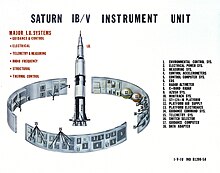

[31] The IU's structural ring had two responsibilities: provide a mounting location for IBM's electronics and hold everything on top of it.

[14] S-IU-200D/500D was the second IU to be built, with the ring completed in January 1965 and electronic components from IBM installed by February 1.

S-IC-D was the first to be built by Boeing at the Michoud Assembly Facility, New Orleans using the tooling that had been developed in Huntsville.

[30] The first stage was lifted into place in the dynamic test stand January 13, 1966 in the picture top right.

[30] S-II-S, which North American Aviation's Space and Information Systems Division (S&ID) at Seal Beach had completed by January 31, was re-designated as S-II-S/D to be used for dynamic testing.

S-II-F was shipped from S&ID, Seal Beach, California on February 20, 1966, to Kennedy Space Center where it arrived March 4.

SA-500F was completed in the Vehicle Assembly Building (VAB), tested for stability against swaying in the wind,[35] and rolled out to the launch pad May 25, 1966, on Mobile Launcher-1 (ML-1).

[3][21][34] After facilities checkout at KSC was completed, the remaining components of SA-500F were then transferred to MSFC for inclusion in SA-500D: the Apollo boilerplate BP-27 and S-II-F/D.

The second stage was modified for dynamic testing, and shipped by Posideon from KSC on October 29 to arrive at MSFC November 10, 1966.

The third stage was added to the stack November 30, and the Instrument Unit and boilerplate Apollo were installed in December.

Testing produced "several minor irregularities indicating the need for possible engineering changes" which were addressed during March, 1967.

[21] Dynamic testing examined "the vehicle's response to lateral, longitudinal, and torsional excitation, simulating those that would be experienced in flight.

The vehicle was "mounted on a hydrodynamic support system made up of four hydraulic/pneumatic pedestals to permit a simulated unrestrained reaction."

Forces were applied to the tail of the rocket to simulate engine thrusting, and various other flight factors were fed to the vehicle to test reactions.

The tests were mandatory before the Center could certify that the guidance system would hold the rocket on course when it was launched.

The dynamic testing resulted in "several slight modifications" to the final flight vehicle.

SA-500D was installed in 1969, and the (renamed) Alabama Space and Rocket Center opened in 1970 showcasing articles that could otherwise only be seen by NASA and Army workers at Redstone Arsenal.

Analysis by Conservation Solutions, Incorporated determined significant damage from both weather and pest infestations.

[5] Restoration culminated in July 2007 when the Saturn V was moved into a building designed as protection for the artifact and to provide additional museum facilities.

[46][47] On May 3, 2012, an unknown person fired three .308 caliber bullets from Interstate 565 at the Davidson Center, breaking three windows.

LES 006/BP-14 was later reassigned a second time to BP-23A, used on PA-2 (Pad Abort 2), and was destroyed as part of testing.

[52] BP-27, the dynamic test boilerplate article, is on display at the U.S. Space and Rocket Center atop the vertical Saturn I.