Severn Tunnel

Recognising the value of such a tunnel, the GWR sought its development, tasking Hawkshaw with its design and later contracting the civil engineer Thomas A. Walker to undertake its construction, which commenced in March 1873.

Following its opening, the tunnel quickly formed a key element of the main trunk railway line between southern England and South Wales.

Originally, during much of the steam era, a large number of pilot and banking locomotives were required to assist heavy trains traverse the challenging gradients of the tunnel, which were deployed from nearby marshalling yards.

The Severn Tunnel forms a critical part of the trunk railway line between southern England and South Wales, and carries an intensive passenger train service as well as significant levels of goods traffic.

The GWR original ventilation arrangement was to extract air at Sudbrook, but the exhaust gases from steam train operation led to premature corrosion of the fan mechanism.

[citation needed] On average, it has been determined that around 11,000,000 imperial gallons (50,000,000 L) per day of fresh (spring) water are typically being pumped from the tunnel; this is normally released directly into the adjacent River Severn.

Access and personal safety difficulties mean that significant work tasks can only be performed during temporary line closure, during which trains are normally diverted via Gloucester.

Officials within the Great Western Railway (GWR) Company soon realised that the rail journey time between the two locations could be significantly shortened by construction of a tunnel directly underneath the River Severn.

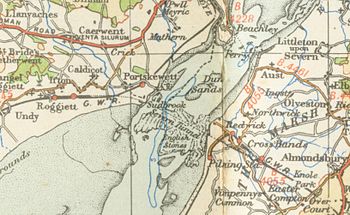

On 27 June 1872, the company obtained an Act of Parliament which authorised the construction of the envisioned railway tunnel as a replacement for the ferry between Portskewett, Monmouthshire and New Passage, Gloucestershire.

[5] On 18 March 1873, construction activity commenced using labourers employed directly by the GWR; this initial work was focused on the sinking of a shaft, possessing a diameter of 15 feet (4.6 m) at Sudbrook and a smaller drainage heading near the Pennant Measures.

To achieve this required holding the Great Spring in check, which in turn was accomplished via the installation of greatly-increased pumping facilities, while a diver also had to be sent down a shaft and 330 yards (300 m) along the tunnel heading to close a watertight door in the workings, sealing off the waters.

[5] During November 1880, this troublesome task was finally achieved by the lead diver, Alexander Lambert, who was equipped with Henry Fleuss' newly developed self-contained rebreather apparatus, avoiding the need for the trailing hose of standard diving dress.

[9] It had been originally assumed that the continuous brickwork lining of the tunnel would withstand the groundwater pressure, thus the drainage sluice valve on the side heading was closed and all but one of the pumps were taken from the site.

[10][11] At the newly built Severn Tunnel Junction station, the GWR built a major marshalling yard, which: distributed east and north, sending coal from the South Wales Valleys towards London and the Midlands; created mainline and localised mixed-traffic freight from goods shipped in from the Midlands, the Southwest and along the Thames Valley, both westwards into Wales and vice versa.

[5] During the 1930s, the availability of the reliable fresh water supply from the Great Spring was a significant contributing factor in favour of the selection of an adjacent site to be established as the Royal Navy Propellant Factory, Caerwent.

The subsequent accident investigation, while unable to reach a firm conclusion on the cause, indicated that the axle counters used for detecting train movements in the tunnel may have been accidentally reset.

[citation needed] In 2002, two Class 121s were overhauled by LNWR, Crewe for use as a Network Rail emergency train that was stabled near Severn Tunnel Junction station.

The service functioned as a rail-based alternative to the Aust Ferry, which was operated under an erratic timetable determined by the tides, or lengthy road journeys via Gloucester.

The rail shuttle service was continued after the end of World War II, but was ultimately made redundant by the opening of the Severn Bridge in 1966, leading to its discontinuation shortly thereafter.

[23] During that time, alternative means of travel were either a longer train journey via Gloucester, or a bus service between Severn Tunnel Junction and Bristol Parkway stations.

[24] Following the completion of this work, which involved the installation of 8.7 miles (14 km) of copper contact wires using 1,700 vertical drop tubes and 857 anchoring points at a rough cost of £10 million to perform, the tunnel was reopened to regular traffic on 22 October 2016.