Snap-fit

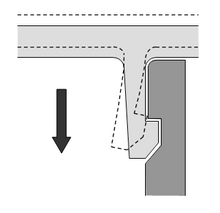

Snap-fits, as integral attachment features, are an alternative to assembly using nails or screws, and have the advantages of speed and no loose parts.

Snap-fit connectors can be found in everyday products such as battery compartment lids, snap fasteners and pens.

Some of the oldest snap-fits found are snap fasteners, or buttons, shown on the Chinese Terracotta Army featuring soldiers from the late Warring States period.

With the development of new flexible yet springy materials, such as molded plastic, and new manufacturing processes, many new variations in these types of connectors have been invented, and are commonly called snap-fits.

However, one major risk when the cooling of the mold finishes is the product shrinking causing errors in the attachment parts.

Building a snap-fit design requires more precise engineering than a screw or nail assembly, and is often more expensive.

[3] The high production costs are due to the amount of calculation and precision that must be done in order to create a strong snap-fit.

These types of snap-fits may have a spring in place; so that when activated, the locked in piece is released and put into action.