Safran Aircraft Engines

The company employs around 15,700 people across 35 production sites, offices, and MRO facilities worldwide and files an average of nearly 500 patents each year.

Established during the 1970s, the CFM56 was not an early success; by April 1979, the joint venture had not received a single order in five years and was allegedly two weeks away from being dissolved.

[14] It fulfills numerous stringent performance criteria, including a high thrust-to-weight ratio, low fuel consumption across all flight regimes, and a long engine life.

It is of a modular design for ease of construction and maintenance, as well as to enable older engines to be retrofitted with improved subsections upon availability, such as existing M88-2s being upgraded to M88-4E standard.

GE Aviation was involved through its Italian subsidiary Avio Aero, providing the gearbox and the low-pressure turbine.To be certified, a blade-out event has to be extremely improbable, less than once every billion flight hours as its resin-transfer molding (RTM) carbon fiber fan blades will be supported by the in-service LEAP experience.

[32] During December 2019, Safran and MTU announced an agreement to found a 50/50 joint venture to manage the development, production, and after-sales support activities of the new military aero engine intended to power the Future Combat Air System.

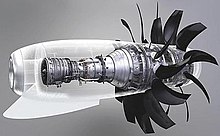

[33] In June 2021, Safran presented an updated architecture for its RISE open rotor concept, with a single to 144-156 in (365-396 cm) fan with variable pitch blades forward of a row of static guide vanes, to deliver 30,000lb of thrust (133 kN) with 20% better efficiency than the CFM LEAP.