Solar thermal energy

High-temperature collectors concentrate sunlight using mirrors or lenses and are generally used for fulfilling heat requirements up to 300 °C (600 °F) / 20 bar (300 psi) pressure in industries, and for electric power production.

[2] Augustin Mouchot demonstrated a solar collector with a cooling engine making ice cream at the 1878 Universal Exhibition in Paris.

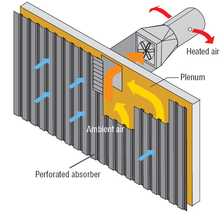

A Trombe wall is a passive solar heating and ventilation system consisting of an air channel sandwiched between a window and a sun-facing thermal mass.

During the ventilation cycle, sunlight stores heat in the thermal mass and warms the air channel causing circulation through vents at the top and bottom of the wall.

Solar-supplied STES technology has been advanced primarily in Denmark,[15] Germany,[16] and Canada,[17] and applications include individual buildings and district heating networks.

Centralized district heating round the clock is also feasible with concentrated solar thermal (CST) storage plant.

The International Energy Agency (IEA) Solar Heating and Cooling program (IEA-SHC) task groups working on further development of the technologies involved.

Modern uses include concentrating brine solutions used in leach mining and removing dissolved solids from waste streams.

Technologies in solar drying include ultra low cost pumped transpired plate air collectors based on black fabrics.

Solar thermal energy is helpful in the process of drying products such as wood chips and other forms of biomass by raising the temperature while allowing air to pass through and get rid of the moisture.

These reflectors have a flexible reflective surface that is able to change its curvature to adjust to seasonal variations in the incident angle of sunlight.

[32] Built in 1999 by the Brahma Kumaris, the world's largest Scheffler reflector system in Abu Road, Rajasthan India is capable of cooking up to 35,000 meals a day.

[28] Dr Lin Zhao of MIT published a peer-reviewed academic journal in Joule detailing their design for a solar autoclave for the sterilisation of surgical instruments without electricity.

[34] A prototype, which incorporates inexpensive aerogel was successfully demonstrated at a hospital in Mumbai in conjunction with IIT Bombay, Indian Institute of Technology.

One proposal for very high temperatures is to use liquid fluoride salts operating between 700 °C (1300 °F) to 800 °C (1500 °F), using multi-stage turbine systems to achieve 50% or more thermal efficiencies.

The principal advantage of CSP is the ability to efficiently add thermal storage, allowing the dispatching of electricity over up to a 24-hour period.

Although only a small percentage of the desert is necessary to meet global electricity demand, still a large area must be covered with mirrors or lenses to obtain a significant amount of energy.

In 2010 the Bureau of Land Management approved nine large-scale solar projects, with a total generating capacity of 3,682 megawatts, representing approximately 40,000 acres.

However, seasonal changes in the angle of sunlight parallel to the trough does not require adjustment of the mirrors, since the light is simply concentrated elsewhere on the receiver.

The glasshouse creates a protected environment to withstand the elements that can negatively impact reliability and efficiency of the solar thermal system.

Sheltering the mirrors from the wind allows them to achieve higher temperature rates and prevents dust from building up as a result from exposure to humidity.

[citation needed] According to its developer, Rispasso Energy, a Swedish firm, in 2015 its Dish Sterling system being tested in the Kalahari Desert in South Africa showed 34% efficiency.

These systems aim to offer lower overall costs by sharing a receiver between several mirrors (as compared with trough and dish concepts), while still using the simple line-focus geometry with one axis for tracking.

Even short term storage can help by smoothing out the "duck curve" of rapid change in generation requirements at sunset when a grid includes large amounts of solar capacity.

Heat is transferred to a thermal storage medium in an insulated reservoir during the day, and withdrawn for power generation at night.

Thermal storage media include pressurized steam, concrete, a variety of phase change materials, and molten salts such as calcium, sodium and potassium nitrate.

[63] Molten salt is used to transport heat in solar power tower systems because it is liquid at atmospheric pressure, provides a low-cost medium to store thermal energy, its operating temperatures are compatible with today's steam turbines, and it is non-flammable and nontoxic.

Inorganics are advantageous with greater phase-change enthalpy, but exhibit disadvantages with undercooling, corrosion, phase separation, and lack of thermal stability.

The greater phase-change enthalpy in inorganic PCMs make hydrate salts a strong candidate in the solar energy storage field.

The conflict is illustrated by plans of Solar Millennium, a German company, to build a plant in the Amargosa Valley of Nevada which would require 20% of the water available in the area.