Sollac

In 1970 the company, under pressure from the French government, began to develop a large new continuous strip mill in the south of France.

After World War II (1939–45) the United States wanted to ensure that the French steel industry could compete effectively with the Ruhr.

[2] The main reason for the merger was to implement a continuous rolling mill to reduce costs and satisfy the expected growing market for automobiles and consumer goods.

[1] In 1948 Léon Daum promoted the creation of Sollac as a joint-venture flat steel manufacturer.

[6] Each company supplied its share of cast iron or steel, which Sollac turned into sheet metal, charging cost price.

[6] The founders included:[6][5] The Sollac project was submitted by France to the Organisation of European Economic Cooperation (OEEC) in April 1949, which had representatives of all the Marshall Plan countries.

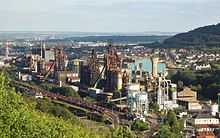

[7] The foundation stone for the Sollac mill was laid on 23 December 1949 in the small village of Serémange on the banks of Fensch river.

[7] In 1950 the company formed an association with Continental Foundry and Machines for manufacture of pilger rolls for continuous mills.

[10] In September 1954 Jules Aubrun was asked by Sollac to assume the post of president, replacing Léon Daum, who had been called to serve in the High Authority of the European Coal and Steel Community in Luxembourg.

In 1968 a new Sacilor plant was being built in the Moselle valley at Gandrange, expected to have a capacity of 1.6 million tons by 1970.

[18] Sollac would have preferred a site near Le Havre, since it would have been closer to large markets, but the government's regional development plans took priority.

[19] Solmer (Societé Lorraine et Méridionale de Laminage Continu) was formed in November 1970 as a Sollac subsidiary to build and operate the new plant.

[20] At the same time, Usinor decided to increase the capacity of its Dunkirk plant to 8 million tons per year.

[21] By 1971 Wendel-Sidélor was the largest steel producer in France, owning Sacilor, the majority of Sollac, and many smaller facilities.

[24] After a delay due to the March 1978 elections, the cabinet released details of their rescue plan on 20 September 1978.

The Thomas steel plant at Hagandange was closed, and Sollac obtained new oxygen furnaces and two continuous casters.

It converted iron ore and coal into steel rolls in a continuous process, producing 6 million tonnes annually.

However, Sollac was struggling due to decline in demand from the automobile and construction industries in Europe, with prices falling and excess steel piling up.

It also supplied steel slabs to the second hot rolling mill of the unit located in Sérémange in Lorraine.