Split pin

Typically made of thick wire with a half-circular cross section, split pins come in multiple sizes and types.

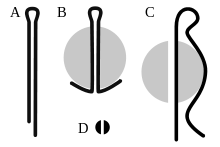

Once inserted, the two ends of the pin are bent apart, locking it in place (figure B).

[5] Split pins are typically made of soft metal, making them easy to install and remove, but also making it inadvisable to use them to resist strong shear forces.

The extended prong type is popular because the difference in length of the two tines makes it easier to separate them.

[clarification needed] The diameters of split pins are standardized.

A: New split pin

B: Installed split pin

C: R-clip

D: Cross-section of a new split pin