Spray foam

Side B contains a polyol, which reacts with isocyanates to make polyurethane, and a mixture of other chemicals, including catalysts (which help the reaction to occur), flame retardant, blowing agents and surfactants.

This expansion makes it useful as a specialty packing material which forms to the shape of the product being packaged and produces a high thermal insulating value with virtually no air infiltration.

[6] As a result of the high thermal resistance of the gas, spray polyurethane insulation typically has an initial R-value around R-3.4 to R-6.7 per inch.

Engineered packaging principles are designed to protect sculptures, vases, large fossils, lamp bases, busts, computers, furniture, chandeliers and other objects of unusual shape.

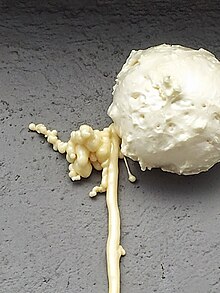

It is a semi-rigid material with a sponge-like appearance that expands during installation and creates small, open cells that are filled with carbon dioxide.

Due to its ability to expand during the application process, it fills cracks, crevices and voids and adheres to irregular surfaces or substrates to form an air sealing insulation.

Unlike medium-density closed-cell SPF, thinner layers of ocSPF are not particularly effective as vapour barrier because the air infiltrates through the open cell structure.

A hard but flexible layer of rigid foam is then created and seals all the tiles to each other and to the steel structure.

This spraying method, especially very popular in Thailand, is used not only against heavy leaks but helps also as insulation against the enormous heat the roofs constantly face.

This tropical heat causes the steel substructure that supports many roofs in that part of the world, to continuously expand and contract, changing slightly the position of the tiles resting on top of them.

However, if applied incorrectly or in damp spaces, spray foam insulation can trap moisture and destroy the roof.

[14] As a result, very few mortgage lenders in the UK will offer a loan to buy or to refinance any home that has any spray foam insulation, especially the closed-cell type.

Every installer of CAN/ULC-S705.1 compliant medium density, spray applied foam must be licensed in order to spray foam and hold valid photo ID issued by their Quality Assurance Program (QAP) provider showing their license is in good standing.

Insulation properly deployed can be part of a system designed to protect against moisture, which provides the benefit of reducing the chance of harmful mold, mildew and rotting of wood.

In addition to building temperature and moisture control, spray foam insulation is often used to reduce noise.

Most closed-cell spray foam was formed using hydrofluorocarbon (HFC) blowing agents that have high global warming potential, partially or completely offsetting the climate benefits of the energy savings they can offer.

The rule increased the alternatives list and restricted the use of high-GWP hydrofluorocarbons (HFCs) in foam blowing.

Individuals with chronic HP often experience progressively more difficult breathing, fatigue, and weight loss.