Standing rigging

In the late 20th Century, racing yachts adopted composite fiber lines for standing rigging, with the goal of reducing weight and windage aloft.

Semi-rigid stainless steel wire is by far the most common as it combines extreme strength, relative ease of assembling and rigging with reliability.

Unlike rigid stainless steel rod, it is comparatively easy to recognize wear and stress as individual strands (normally 19) break often near a swage fitting, and can be inspected while standing.

[3] Solid rod stainless steel is more aerodynamic so is often used in extreme racing yachts but it is difficult to see stress as this requires professional inspection such as dye penetrate testing or x-raying.

[6] Each additional mast segment was supported fore and aft by a series of stays that led forward.

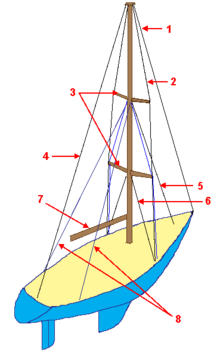

Key: 1. Forestay 2. Shroud 3. (Spreaders) 4. Backstay 5. Inner forestay 6. Sidestay 7. (Boom) 8. Running backstays