Steam motor

An early example with the all-in-one (coach, baggage, mail and/or express matter compartments) was photographed working on the Nashville, Chattanooga & St. Louis Railroad during the American Civil War, in Tennessee, circa 1863-64.

[2] One American firm, Grice & Long, devised various versions in the mid-1860s for use on suburban and city street railways, using their proprietary mechanical patents.

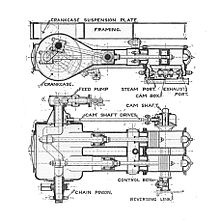

In the most modern form of steam motors, the crankshaft and often the valve gear, was enclosed within a crankcase that contained an oil sump.

Much earlier examples, e.g. mid-19th century, employed all manner of mechanisms with manual lubrication through small drip cups.

Gear drives required the steam motor to be mounted low-down, alongside the axle.

Geared drives appear in some of the earliest steam motor cars used in North America, although more conventional reciprocating drives with either a single power axle or doubled power axles, linked by connecting rods, were quite common.

Fuel and water consumption savings was one more important consideration in most steam motor cars used around the world.

Although other oil-bath systems on steam locomotives, such as the Bulleid chain-driven valve gear, gained a poor reputation for reliability, this was mostly due to the difficulty of sealing such a large container.

Between 1901 and 1908, Ganz Works of Budapest and de Dion-Bouton of Paris collaborated to build a number of railcars for the Hungarian State Railways together with units with de Dion-Bouton boilers, Ganz steam motors and equipments, and Raba carriages built by the Raba Hungarian Wagon and Machine Factory in Győr.

In 1908, the Borzsavölgyi Gazdasági Vasút (BGV), a narrow-gauge railway in Carpathian Ruthenia (today's Ukraine), purchased five railcars from Ganz and four railcars from the Hungarian Royal State Railway Machine Factory with de Dion-Bouton boilers.

The Ganz company started to export steam motor railcars to the United Kingdom, Italy, Canada, Japan, Russia and Bulgaria.

Although the locomotive achieved its goal of avoiding vibration and hammer blow, and its novel boiler and firebrick firebox was also simple and reliable, it was not considered an overall success.

The rotary valvegear absorbed more power to drive it than a conventional design and suffered from problems with thermal expansion.

After a mechanical failure of the valvegear seizing and blocked a main line for several hours, the locomotive was withdrawn and later scrapped.

[10] In the same year, Kyrle Willans[ii][11] suggested that a worn-out conventional locomotive, a Manning-Wardle named Ancoats, could be rebuilt with the boiler and engine of a Sentinel steam wagon in the locomotive's frames, connected by a roller chain drive.

To give greater power, Sentinel patented the concept of using multiple, identical steam motors, each driving one axle.

The railway locomotive might achieve a tractive effort of 123,000 lbf and haul a load for slow shunting work of 650 tons.

The Super-Sentinel engine used two camshafts: inlet and exhaust, placed near the crankshaft in the crankcase and operating the poppet valves through long pushrods.

[23] The crankcase of the engine, together with the crosshead trunk guide, was enclosed and provided with oil splash lubrication.

A small plenum was left exposed between the cylinder's piston rod stuffing box and another gland seal into the crankcase.

Petrol railcars and railbuses were appearing by this time, although they were limited in power and so weight, size and carrying capacity.

He later worked for Henschel of Germany who built trucks, buses, railcars and even locomotives using his steam motor principle.

[27] Rebuilt from a 230 class 4-6-0T tank locomotive as a 4-4-2T, with a longitudinal V12 steam motor driving the two driven axles through a driveshaft.

Each of the three driven axles had a pair of three-cylinder double-acting uniflow steam motors, giving 18 cylinders in total.

The railway was already using Sentinel railcars similar to the LNER pattern, but required a larger multiple unit.

Two were built as four-unit rakes: a locomotive based on the previous railcar chassis and three trailer coaches.

The B-B locomotive used two four wheel bogies, each driven by a six-cylinder motor based on the railcar, for a total of 250 bhp.

These were built as a batch of four, the first of which was sold to Belgium in 1934, followed by three for the Société National des Chemins de Fer en Colombe.

The chassis layout was a Co-Co, with each axle independently driven by a two-cylinder compound Doble steam motor.

The steam motor cars of North America reached their popular apex before the 1880s, with most fabricated to custom designs by small specialty builders before 1875.