Sulfur hexafluoride circuit breaker

Advantages over other media include lower operating noise and no emission of hot gases, and relatively low maintenance.

Sulfur hexafluoride circuit breakers may be used as self-contained apparatus in outdoor air-insulated substations or may be incorporated into gas-insulated switchgear which allows compact installations at high voltages.

Current interruption in a high-voltage circuit breaker is obtained by separating two contacts in a medium, such as sulfur hexafluoride (SF6), having excellent dielectric and arc-quenching properties.

The gas captures the conducting free electrons in the arc to form relatively immobile negative ions.

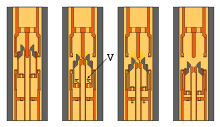

High-voltage circuit breakers have changed since they were introduced in the mid-1950s, and several interrupting principles have been developed that have contributed successively to a large reduction of the operating energy.

The first patents on the use of SF6 as an interrupting medium were filed in Germany in 1938 by Vitaly Grosse (AEG) and independently later in the United States in July 1951 by H. J. Lingal, T. E. Browne and A. P. Strom (Westinghouse).

In 1957, the puffer-type technique was introduced for SF6 circuit breakers, wherein the relative movement of a piston and a cylinder linked to the moving part is used to generate the pressure rise necessary to blast the arc via a nozzle made of insulating material.

This performance was already significant, but the three chambers per pole and the high-pressure source needed for the blast (1.35 MPa) was a constraint that had to be avoided in subsequent developments.

The excellent properties of SF6 led to the fast extension of this technique in the 1970s and to its use for the development of circuit breakers with high interrupting capability, up to 800 kV.

As a direct consequence, the reliability of circuit breakers improved, as verified later on by International Council on Large Electric Systems (CIGRE) surveys.

These developments have been facilitated by the progress made in digital simulations that were widely used to optimize the geometry of the interrupting chamber and the linkage between the poles and the mechanism.

The increased understanding of arc interruption obtained by digital simulations and validation through breaking tests, contribute to a higher reliability of these self-blast circuit breakers.

The thermal and self-blast principles have enabled the use of low-energy spring mechanisms for the operation of high-voltage circuit breakers.

The overpressure produced by the arc energy downstream of the interruption zone is applied on an auxiliary piston linked with the moving part.

The self-blast technique described above is also widely used in SF6 generator circuit breakers, in which the contact system is driven by a low-energy, spring-operated mechanism.

One byproduct, disulfur decafluoride (S2F10), has a toxicity similar to phosgene and does not produce lacrimation or skin irritation, thus providing little warning of exposure.

The higher dielectric strength of the gas allows more compact design or a larger interrupting rating for the same relative size as air-blast circuit breakers.

This also has the desirable effect of minimizing size and weight of the circuit breakers, making foundations and installation less costly.

At very low outdoor temperatures, unlike air, SF6 gas can liquefy, reducing the ability of the circuit breaker to interrupt fault currents.