Surface condenser

[2][3][4][5] There are many fabrication design variations depending on the manufacturer, the size of the steam turbine, and other site-specific conditions.

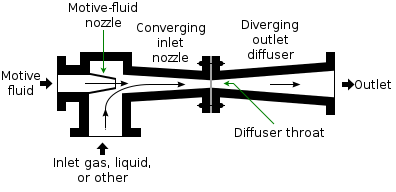

For water-cooled surface condensers, the shell's internal vacuum is most commonly supplied by and maintained by an external steam jet ejector system.

Such an ejector system uses steam as the motive fluid to remove any non-condensible gases that may be present in the surface condenser.

The Venturi effect, which is a particular case of Bernoulli's principle, applies to the operation of steam jet ejectors.

At each end of the shell, a sheet of sufficient thickness usually made of stainless steel is provided, with holes for the tubes to be inserted and rolled.

Some makers also recommend plastic inserts at the entry of tubes to avoid eddies eroding the inlet end.

Generally the tubes are made of stainless steel, copper alloys such as brass or bronze, cupro nickel, or titanium depending on several selection criteria.

Also depending on the steam cycle water treatment for the boiler, it may be desirable to avoid tube materials containing copper.

The tube lengths range to about 85 ft (26 m) for modern power plants, depending on the size of the condenser.

Similarly thermometer pockets are located at inlet and outlet pipes for local measurements of cooling water temperature.

This practice must be strictly regulated to make sure the circulating water returning to the sea or river source is not affected.

On the steam (shell) side of the condenser: The concentration of undissolved gases is high over air zone tubes.

Sacrificial anodes of zinc (being cheapest) plates are mounted at suitable places inside the water boxes.

Tube-side fouling for surface condensers falls into five main categories; particulate fouling like silt and sediment, biofouling like slime and biofilms, scaling and crystallization such as calcium carbonate, macrofouling which can include anything from zebra mussels that can grow on the tubesheet, to wood or other debris that blocks the tubing, and finally, corrosion products (discussed previously).

A variety of methods for cleaning are available, including online and offline options, depending on the plant's site-specific conditions.