Tensile testing

[2] From these measurements the following properties can also be determined: Young's modulus, Poisson's ratio, yield strength, and strain-hardening characteristics.

[3] Uniaxial tensile testing is the most commonly used for obtaining the mechanical characteristics of isotropic materials.

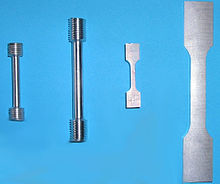

The gauge section's smaller diameter also allows the deformation and failure to occur in this area.

Each system has advantages and disadvantages; for example, shoulders designed for serrated grips are easy and cheap to manufacture, but the alignment of the specimen is dependent on the skill of the technician.

For soft and porous materials, like electrospun nonwovens made of nanofibers, the specimen is usually a sample strip supported by a paper frame to favour its mounting on the machine and to avoid membrane damaging.

Both ends of the specimens should have sufficient length and a surface condition such that they are firmly gripped during testing.

The initial gauge length Lo is standardized (in several countries) and varies with the diameter (Do) or the cross-sectional area (Ao) of the specimen as listed The following tables gives examples of test specimen dimensions and tolerances per standard ASTM E8.

[5] The electromechanical machine uses an electric motor, gear reduction system and one, two or four screws to move the crosshead up or down.

Manual configurations require the operator to adjust a needle valve in order to control the load rate.

A general comparison shows that the electromechanical machine is capable of a wide range of test speeds and long crosshead displacements, whereas the hydraulic machine is a cost-effective solution for generating high forces.

The machine must be able to apply the force quickly or slowly enough to properly mimic the actual application.

Finally, the machine must be able to accurately and precisely measure the gauge length and forces applied; for instance, a large machine that is designed to measure long elongations may not work with a brittle material that experiences short elongations prior to fracturing.

This situation can be minimized by using spherical seats or U-joints between the grips and the test machine.

[6] Newer test machines have digital time, force, and elongation measurement systems consisting of electronic sensors connected to a data collection device (often a computer) and software to manipulate and output the data.

[5] When dealing with porous and soft materials, as electrospun nanofibrous membranes, the application of the above stress formula is problematic.

In this case, the normalization of load with respect to the specimen mass instead of the cross-section area (A) is recommended to obtain reliable tensile results.

While there are many ways to test creep, tensile testing is useful for materials such as concrete and ceramics that behave differently in tension and compression, and thus possess different tensile and compressive creep rates.

Additionally, specialized tensile creep testing equipment may include incorporated high temperature furnace components to aid diffusion.