Tire

Pneumatic tires are used on many vehicles, including cars, bicycles, motorcycles, buses, trucks, heavy equipment, and aircraft.

Moreover, the regular use of tires produces micro-plastic particles that contain these chemicals that both enter the environment and affect human health.

[4] The earliest tires were bands of leather,[9] then iron (later steel) placed on wooden wheels used on carts and wagons.

They employed inventor Charles Kingston Welch and acquired other rights and patents, which allowed them some limited protection of their Pneumatic Tyre business's position.

Disadvantages, besides a higher cost than that of bias tires, are a harder ride at low speeds and generally worse performance on rough terrain.

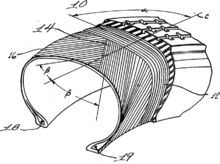

[52] Since the tread and sidewalls share their casing plies, the tire body flexes as a whole, providing the main advantage of this construction, better traction and smoother motion on uneven surfaces, with a greater tendency to conform to rocky ground and throw off mud and clay, especially because the rubber is usually of a softer compound than that used on radial tires.

However, this conformity increases a bias tire's rolling resistance, and its stiffness allows less control, traction, and comfort at higher speeds, while shear between its overlapping plies causes friction that generates heat.

This construction provides a smoother ride that is similar to the bias tire, while lessening rolling resistance because the belts increase tread stiffness.

The design was introduced by Armstrong, while Goodyear made it popular with the "Polyglas" trademark tire featuring a polyester carcass with belts of fiberglass.

Many tires used in industrial and commercial applications are non-pneumatic, and are manufactured from solid rubber and plastic compounds via molding operations.

Tire production starts with bulk raw materials such as rubber, carbon black, and chemicals and produces numerous specialized components that are assembled and cured.

[72] Tires treads may incorporate a variety of distances between slots (pitch lengths) to minimize noise levels at discrete frequencies.

This essential component is constructed with robust steel cables encased in durable, specially formulated rubber designed to resist stretching.

The bead's design ensures a secure, non-slip connection, preventing the tire from rotating independently from the wheel during vehicle motion.

Additionally, the interplay between the bead's dimensions and the wheel's width significantly influences the vehicle's steering responsiveness and stability, as it helps to maintain the tire’s intended shape and contact with the road.

The sidewall contains air pressure and transmits the torque applied by the drive axle to the tread to create traction but supports little of the weight of the vehicle, as is clear from the total collapse of the tire when punctured.

To achieve this the steel cords are coated in a thin layer of brass,[83] various additives will also be added to the rubber to improve binding, such as resorcinol/HMMM mixtures.

The elastomer, which forms the tread and encases the cords to protect them from abrasion and hold them in place, is a key component of pneumatic tire design.

It can be composed of various composites of rubber material – the most common being styrene-butadiene copolymer – with other chemical compounds such as silica and carbon black.

Optimizing rolling resistance in the elastomer material is a key challenge for reducing fuel consumption in the transportation sector.

[84] However, there is a trade-off between rolling resistance and wet traction and grip: while low rolling resistance can be achieved by reducing the viscoelastic properties of the rubber compound (low tangent (δ)), it comes at the cost of wet traction and grip, which requires hysteresis and energy dissipation (high tangent (δ)).

Therefore, the ratio of the two monomers in the styrene-butadiene copolymer is considered key in determining the glass transition temperature of the material, which is correlated to its grip and resistance properties.

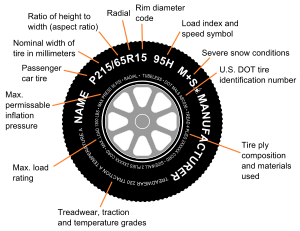

The National Institute of Metrology Standardization and Industrial Quality (INMETRO) is the Brazilian federal body responsible for automotive wheel and tire certification.

An (upper case) "E" indicates that the tire is certified to comply with the dimensional, performance, and marking requirements of ECE regulation 30.

[2] A 2023 literature review from Imperial College London, warned of both the toxic chemicals and microplastics produced from tire wear as having potential widespread serious environmental and health consequences.

[2] Moreover, burning of tires releases these chemicals as air pollutants as well as leaving toxic residues, that can have significant effects on local communities and first responders.

[128] Some facilities are permitted to recycle scrap tires by chipping and processing them into new products or selling the material to licensed power plants for fuel.

[129] Many states have regulations as to the number of scrap tires that can be held on-site, due to concerns with dumping, fire hazards, and mosquitoes.

[130] Of particular concern is evidence that some of the compounds that leach from tires into the water contain hormone disruptors and cause liver lesions.

On the other hand, the pre-cure method involves the application of a ready-made tread band on the buffed and prepared casing, which later is cured in an autoclave so that vulcanization can occur.