Vacuum flask

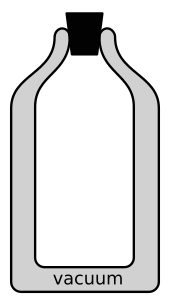

The gap between the two flasks is partially evacuated of air, creating a near-vacuum which significantly reduces heat transfer by conduction or convection.

Dewar refused to patent his invention; this allowed others to develop the flask using new materials such as glass and aluminium, and it became a significant tool for chemical experiments and also a common household item.

[4] The manufacturing and performance of the Thermos bottle was significantly improved and refined by the Viennese inventor and merchant Gustav Robert Paalen, who designed various types for domestic use, which he also patented, and distributed widely, through the Thermos Bottle Companies in the United States, Canada and the UK, which bought licences for respective national markets.

The gap between the two vessels is partially evacuated of air, creating a partial-vacuum which reduces heat conduction or convection.

In laboratories and industry, vacuum flasks are often used to hold liquefied gases (commonly liquid nitrogen with a boiling point of 77 K) for flash freezing, sample preparation and other processes where creating or maintaining an extreme low temperature is desired.

Larger vacuum flasks store liquids that become gaseous at well below ambient temperature, such as oxygen and nitrogen; in this case the leakage of heat into the extremely cold interior of the bottle results in a slow boiling-off of the liquid so that a narrow unstoppered opening, or a stoppered opening protected by a pressure relief valve, is necessary to prevent pressure from building up and eventually shattering the flask.

The insulation of the vacuum flask results in a very slow "boil" and thus the contents remain liquid for long periods without refrigeration equipment.

The principle of the vacuum flask makes it ideal for storing certain types of rocket fuel, and NASA used it extensively in the propellant tanks of the Saturn launch vehicles in the 1960s and 1970s.

[19] In the oil and gas industry, Dewar flasks are used to insulate the electronic components in wireline logging tools.

[20] Conventional logging tools (rated to 350 °F) are upgraded to high-temperature specifications by installing all sensitive electronic components in a Dewar flask.

Proper preparation of the Dewar vacuum flask by tempering prior to use is advised to maintain and optimize the functioning of the unit.