Pyrolysis

The word pyrolysis is coined from the Greek-derived elements pyro- (from Ancient Greek πῦρ : pûr - "fire, heat, fever") and lysis (λύσις : lúsis - "separation, loosening").

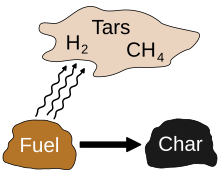

In general, pyrolysis of organic substances produces volatile products and leaves char, a carbon-rich solid residue.

Pyrolysis is one of the various types of chemical degradation processes that occur at higher temperatures (above the boiling point of water or other solvents).

In the chemical process industry, pyrolysis refers to a partial thermal degradation of carbonaceous materials that takes place in an inert (oxygen free) atmosphere and produces both gases, liquids and solids.

[16] Pyrolysis was instrumental in the discovery of many chemical substances, such as phosphorus from ammonium sodium hydrogen phosphate NH4NaHPO4 in concentrated urine, oxygen from mercuric oxide, and various nitrates.

[citation needed] Pyrolysis generally consists in heating the material above its decomposition temperature, breaking chemical bonds in its molecules.

The fragments usually become smaller molecules, but may combine to produce residues with larger molecular mass, even amorphous covalent solids.

[citation needed] In many settings, some amounts of oxygen, water, or other substances may be present, so that combustion, hydrolysis, or other chemical processes may occur besides pyrolysis proper.

Sometimes those chemicals are added intentionally, as in the burning of firewood, in the traditional manufacture of charcoal, and in the steam cracking of crude oil.

[citation needed] Conversely, the starting material may be heated in a vacuum or in an inert atmosphere to avoid chemical side reactions (such as combustion or hydrolysis).

The original vascular structure of the wood and the pores created by escaping gases combine to produce a light and porous material.

[30] Terra preta is much sought by local farmers for its superior fertility and capacity to promote and retain an enhanced suite of beneficial microbiota, compared to the typical red soil of the region.

For their first workable electric lamps, Joseph Wilson Swan and Thomas Edison used carbon filaments made by pyrolysis of cotton yarns and bamboo splinters, respectively.

Other sources of organic matter as feedstock for pyrolysis include greenwaste, sawdust, waste wood, leaves, vegetables, nut shells, straw, cotton trash, rice hulls, and orange peels.

[23] The low quality of oils produced through pyrolysis can be improved by physical and chemical processes,[37] which might drive up production costs, but may make sense economically as circumstances change.

[41] This one-step process produces hydrogen in high volume at low cost (less than steam reforming with carbon sequestration).

In 2015, a company called Monolith Materials built a pilot plant in Redwood City, CA to study scaling Methane Pyrolysis using renewable power in the process.

[61] The Australian company Hazer Group was founded in 2010 to commercialise technology originally developed at the University of Western Australia.

It is completing a commercial demonstration project to produce renewable hydrogen and graphite from wastewater and iron ore as a process catalyst use technology created by the University of Western Australia (UWA).

"[63] The Hazer Group has collaboration agreements with Engie for a facility in France in May 2023,[64] A Memorandum of Understanding with Chubu Electric & Chiyoda in Japan April 2023[65] and an agreement with Suncor Energy and FortisBC to develop 2,500 tonnes per Annum Burrard-Hazer Hydrogen Production Plant in Canada April 2022[66][67] The American company C-Zero's technology converts natural gas into hydrogen and solid carbon.

[71] The process of metalorganic vapour-phase epitaxy (MOCVD) entails pyrolysis of volatile organometallic compounds to give semiconductors, hard coatings, and other applicable materials.

Raw polycrystalline silicon is produced by the chemical vapor deposition of silane gases: Gallium arsenide, another semiconductor, forms upon co-pyrolysis of trimethylgallium and arsine.

[34][81] In early November 2021, the U.S. State of Georgia announced a joint effort with Igneo Technologies to build an $85 million large electronics recycling plant in the Port of Savannah.

The project will focus on lower-value, plastics-heavy devices in the waste stream using multiple shredders and furnaces using pyrolysis technology.

Tobacco Waste (TW) also contains inorganic (metal) contents, which was determined using an inductively coupled plasma-optical spectrometer.

[83] Thermo-gravimetric analysis was used to thermally degrade four samples (TLW, TSW, glycerol, and guar gum) and monitored under specific dynamic temperature conditions.

CaCO3 is used in cigarette papers and filter material, leading to the explanation that degradation of CaCO3 causes pure CO2 reacting with CaO in a dynamic equilibrium state.

Hydrogen, Methane, Ethane, Carbon Dioxide, and Ethylene all are produced when the thermolytic rate of TLW began to be retarded at greater than or equal to 500 °C.

One-stepwise pyrolysis was not that effective on activating CO2 on carbon rearrangement due to the high quantities of liquid pyrolysates (tar).

[106][107] In recent years, machine learning has attracted significant research interest in predicting yields, optimizing parameters, and monitoring pyrolytic processes.