Vapor barrier

Materials have a moisture vapor transmission rate (MVTR) that is established by standard test methods.

Other wetting mechanisms, such as wind-borne rain, capillary wicking of ground moisture, air transport (infiltration), are equally important.

Good design and practice involve controlling the wetting of building assemblies from both the exterior and interior.

A heating degree day is a unit that measures how often outdoor daily dry-bulb temperatures fall below an assumed base, normally 18 °C (65 °F).

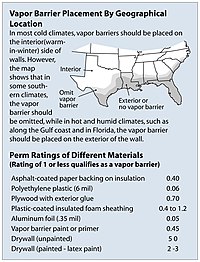

In humid regions where warm-weather cooling predominates within buildings, the vapor barrier should be located toward the exterior side of insulation.

In relatively mild or balanced climates, or where assemblies are designed to minimize condensation conditions, a vapor barrier may not be necessary at all.

In most climates it is often better to have a vapor-open building assembly, meaning that walls and roofs should be designed to dry:[6] either to the inside, the outside, or both, so the ventilation of water vapor should be taken into consideration.

A slab-on-grade or basement floor should be poured over a cross-laminated polyethylene vapor barrier over 4 inches (10 cm) of granular fill to prevent wicking of moisture from the ground and radon gas incursion.

Inside a steel building, water vapor will condense whenever it comes into contact with a surface that is below the dew point temperature.