Vickers hardness test

The basic principle, as with all common measures of hardness, is to observe a material's ability to resist plastic deformation from a standard source.

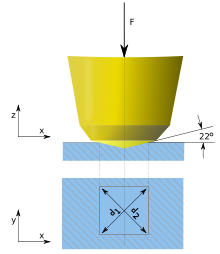

It was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter should have high resistance to self-deformation.

As two tangents to the circle at the ends of a chord 3d/8 long intersect at 136°, it was decided to use this as the included angle between plane faces of the indenter tip.

The angle was varied experimentally and it was found that the hardness value obtained on a homogeneous piece of material remained constant, irrespective of load.

[2] Accordingly, loads of various magnitudes are applied to a flat surface, depending on the hardness of the material to be measured.

The HV number is then determined by the ratio F/A, where F is the force applied to the diamond in kilograms-force and A is the surface area of the resulting indentation in square millimeters.

[citation needed] which can be approximated by evaluating the sine term to give, where d is the average length of the diagonal left by the indenter in millimeters.

To calculate Vickers hardness number (VHN) using SI units one needs to convert the force applied from newtons to kilogram-force by dividing by 9.806 65 (standard gravity).

Vickers hardness numbers are reported as xxxHVyy, e.g. 440HV30, or xxxHVyy/zz if duration of force differs from 10 s to 15 s, e.g. 440HV30/20, where: When doing the hardness tests, the minimum distance between indentations and the distance from the indentation to the edge of the specimen must be taken into account to avoid interaction between the work-hardened regions and effects of the edge.

For thin samples indentation depth can be an issue due to substrate effects.

As a rule of thumb the sample thickness should be kept greater than 2.5 times the indent diameter.

If HV is first expressed in N/mm2 (MPa), or otherwise by converting from kgf/mm2, then the tensile strength (in MPa) of the material can be approximated as σu ≈ HV/c , where c is a constant determined by yield strength, Poisson's ratio, work-hardening exponent and geometrical factors – usually ranging between 2 and 4.

This empirical law depends variably on the work-hardening behavior of the material.

[10] The fin attachment pins and sleeves in the Convair 580 airliner were specified by the aircraft manufacturer to be hardened to a Vickers Hardness specification of 390HV5, the '5' meaning five kiloponds.

On examination, accident investigators found that the sub-standard pins had a hardness value of only some 200–230HV5.