Water-tube boiler

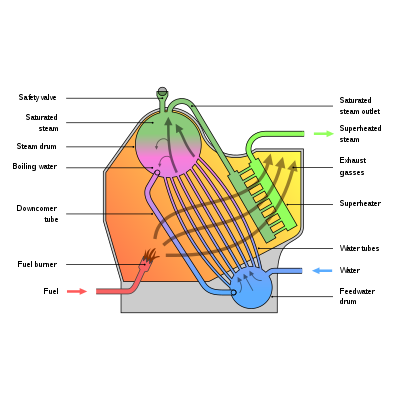

Fuel is burned inside the furnace, creating hot gas which boils water in the steam-generating tubes.

To increase economy of the boiler, exhaust gases are also used to pre-heat combustion air blown into the burners, and to warm the feedwater supply in an economizer.

[4] Modern boilers for power generation are almost entirely water-tube designs, owing to their ability to operate at higher pressures.

One notable exception is in typical nuclear-power stations (Pressurized Water Reactors), where the steam generators are generally configured similar to firetube boiler designs.

In these applications the hot gas path through the "Firetubes" actually carries the very hot/high pressure primary coolant from the reactor, and steam is generated on the external surface of the tubes.

The Norfolk and Western Railway's Jawn Henry was an exception, because it used a steam turbine combined with an electric transmission.

Operating as a compound at a boiler pressure of 2,400 kilopascals (350 psi) it covered over 160,000 kilometres (100,000 mi) successfully.

After a year though, it became clear that any economies were overwhelmed by the extra costs, and it was retired to a museum display at the Franklin Institute in Philadelphia, Pennsylvania.

The original characteristic of the Brotan was a long steam drum running above the main barrel, making it resemble a Flaman boiler in appearance.

Road transport pioneers Goldsworthy Gurney and Walter Hancock both used water-tube boilers in their steam carriages around 1830.

Many manufacturers used variants of the vertical cross-tube boiler, including Atkinson, Clayton, Garrett and Sentinel.

The low water content boiler has a lower and upper header connected by watertubes that are directly impinged upon from the burner.

Originally coal-fired in power stations, they also became widespread in industries that produced combustible waste and required process steam.

Named after its designers, the then Poplar-based Yarrow Shipbuilders, this type of three-drum boiler has three drums in a delta formation connected by watertubes.

Its compact size made it attractive for use in transportable power generation units during World War II.

In order to make it transportable, the boiler and its auxiliary equipment (fuel oil heating, pumping units, fans etc.

Apart from obvious difficulties in cleaning them, this may also give rise to bending forces as the tubes warm up, tending to pull them loose from the tubeplate and creating a leak.