Windscale Piles

The two reactors, referred to at the time as "piles", were built as part of the British post-war atomic bomb project and produced weapons-grade plutonium for use in nuclear weapons.

[2] During the Second World War, Frisch and Rudolf Peierls at the University of Birmingham calculated the critical mass of a metallic sphere of pure uranium-235, and found that as little as 1 to 10 kilograms (2.2 to 22.0 lb) might explode with the power of thousands of tons of dynamite.

[15] The Tube Alloys Directorate was transferred from the Department of Scientific and Industrial Research to the Ministry of Supply on 1 November 1945,[16] and Lord Portal was appointed Controller of Production, Atomic Energy (CPAE), with direct access to the Prime Minister.

[22] The 8 January 1947 meeting of the Gen 163 Committee, a subcommittee of the Gen 75 Committee, agreed to proceed with the development of atomic bombs, and endorsed Portal's proposal to place William Penney, the Chief Superintendent Armament Research (CSAR) at Fort Halstead in Kent, in charge of the development effort,[13] which was codenamed High Explosive Research.

"[24] Through their participation in the wartime Tube Alloys and Manhattan Project, British scientists had considerable knowledge of the production of fissile materials.

[26] Part of the deficit of technical knowledge was addressed by the Montreal Laboratory in Canada, where the ZEEP reactor went critical on 5 September 1945, and the Americans had supplied some irradiated fuel rods for experiments with plutonium separation there.

[29] This was fine for some experimental work, but the production of radioactive isotopes required a more powerful 6,000 kW reactor with a higher neutron flux.

R. G. Newell, who had been the wartime head of the engineering section at the Montreal Laboratory, proposed in a 1946 paper that the reactor be encased in a pressure vessel.

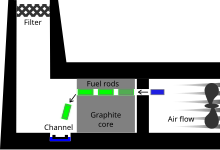

[36] Another, by Risley engineers D. W. Ginns, H. H. Gott and J. L. Dickson, put forward a series of proposals to increase the efficiency of an air cooling system.

These included adding fins to the aluminium cans containing the uranium fuel elements to increase their surface area; and having the cooling air enter the reactor centrally so it could flow outwards instead of being pumped from one end to another.

Harwell engineers J. Diamond and J. Hodge conducted a series of tests which showed that with these innovations, air at atmospheric pressure would suffice for cooling a small reactor for plutonium production, although not a large one for nuclear power.

In their report to Attlee on 1 January 1946, the Chiefs of Staff recommended that two be built, but for the moment it was fixed at one reactor capable of producing 15 bombs per annum.

To avoid any chance of it shrinking, the ratio of water to cement was carefully controlled, and the order in which the concrete was poured was done so as to maximise drying time.

Similar practices were followed while assembling the reactor, with the workers wearing special clothes, and the air inside the biological shield filtered to remove dust.

The Hungarian-American physicist Eugene Wigner had discovered while working at the Manhattan Project's Metallurgical Laboratory in Chicago that graphite, when bombarded by neutrons, suffers dislocations in its crystalline structure, causing a build-up of potential energy.

The scientists were more optimistic, predicting a lifetime of fifteen to thirty-five years, but conceded that Wigner energy-induced expansion might cause the graphite to crack before then.

[50] Harwell physicist William Marley, who had worked at the Manhattan Project's Los Alamos Laboratory during the war,[52] had warned of the possibility of a fire in a control rod being exacerbated by the release of Wigner energy,[52] and when Edward Teller visited Harwell in 1948, he warned that a Wigner energy release might ignite a fuel rod.

In case of emergency, there were also sixteen vertical fail safe rods held above by electromagnets that could drop down into the core under gravity at the flick of a switch.

[55] Instrumentation included devices for measuring the temperature and neutron flux in the core, the speed of the blowers, the control rod positions, and there were various alarms.

On a visit to the X-10 Graphite Reactor at the Oak Ridge National Laboratory in the United States, Cockcroft found that uranium oxide particles had been detected in the vicinity.

Construction involved the materials to build them, which included 200 long tons (200 t) of structural steel, plus bricks, concrete and equipment, being hoisted to the top of the 400-foot (120 m) chimneys.

[62] Enough Windscale plutonium for an atomic bomb was delivered to the weapons division at Aldermaston in August,[63] and Britain's first nuclear device was successfully detonated in the Operation Hurricane test in the Monte Bello Islands in Western Australia on 3 October 1952.

By 17:00 it was reckoned that the accumulated Wigner energy had been released, and the shutdown fans, and then the main blowers, were switched on to cool the core in preparation for restarting.

[65] On 1 March 1955, the prime minister, Winston Churchill, publicly committed the UK to building a hydrogen bomb, and gave the scientists a tight schedule in which to do so.

There were fears that the lead might melt, so this was replaced in December 1956 by a cartridge in which a 1.0-inch (25 mm) diameter rod was encased in aluminium with no annulus or outer can.

[71] In addition to plutonium and tritium, the Windscale Piles also produced polonium-210 (codename LM) for the neutron initiators used in the bombs through irradiation of bismuth.

The board of inquiry's report concluded officially that the fire had been caused by "an error of judgement" by the same people who then risked their lives to contain the blaze.

[95] Decommissioning work commenced in the 1980s, with the sealing of a bioshield, the installation of ventilation and monitoring, the removal of loose fuel elements outside the core, and draining the water duct.

The biggest danger was that of a graphite dust explosion, but with 15 tonnes (15 long tons) of uranium in the reactor, there was still a remote possibility of a criticality accident.

The contaminated chimneys could not simply be knocked over, so they had to be demolished systematically from the top down with core drills, and the rubble transported to the ground a ton at a time on a small goods hoist.