Woodworking

Since Neolithic times, carved wooden vessels are known, for example, from the Linear Pottery culture wells at Kückhofen and Eythra.

Examples of Bronze Age wood-carving include tree trunks worked into coffins from northern Germany and Denmark and wooden folding-chairs.

The site of Fellbach-Schmieden in Germany has provided fine examples of wooden animal statues from the Iron Age.

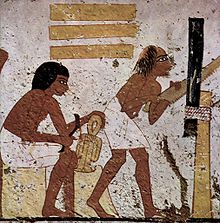

The metal used by the Egyptians for woodworking tools was originally copper and eventually, after 2000 BC bronze as iron working was unknown until much later.

[2] Commonly used woodworking tools included axes, adzes, chisels, pull saws, and bow drills.

[7] The progenitors of Chinese woodworking are considered to be Lu Ban (魯班) and his wife Lady Yun, from the Spring and Autumn period (771 to 476 BC).

This book is filled largely with descriptions of dimensions for use in building various items such as flower pots, tables, altars, etc., and also contains extensive instructions concerning Feng Shui.

The development of Computer Numeric Controlled (CNC) Machines, for example, has made it possible to mass-produce and reproduce products faster, with less waste, and often with more complex design than ever before.

CNC wood routers can carve complicated and highly detailed shapes into flat stock, to create signs or art.

Rechargeable power tools speed up creation of many projects and require much less body strength than in the past, for example when boring multiple holes.

[10] Softwood is most commonly found in the regions of the world with lower temperatures and is typically less durable, lighter in weight, and more vulnerable to pests and fungal attacks in comparison to hardwoods.

They typically have a paler color and a more open grain than hardwoods, which contributes to the tendency of felled softwood to shrink and swell as it dries.

Temperate hardwoods are found in the regions between the tropics and poles, and are of particular interest to wood workers for their cost-effective aesthetic appeal and sustainable sources.

[10] Typically furniture such as tables and chairs is made using solid stock from hardwoods due to its strength and resistance to warping.

[11] Additionally, they also have a greater variety of grain patterns and color and take a finish better which allows the woodworker to exercise a great deal of artistic liberty.

Some furniture, such as the Windsor chair involve green woodworking, shaping with wood while it contains its natural moisture prior to drying.

[14] This hardwood is relatively easy to work with and takes stain well, but its white to light brown color with a straight grain is visually appealing on its own.

[13] Hardwood of the European species Fagus sylvatica is widely used for furniture framing and carcase construction, in plywood, musical instruments (drum shells and piano blocks) and turned items like knobs.

[13] Popular and easy to work with, cherry is in high demand for its reddish-brown color and ease of staining and finishing.

However, mahogany is not typically grown in sustainable forests, and thus runs a steep price at local lumber yards.

[13] Depending on the kind needed, oak can probably be found at a local home center or a lumberyard for a bit pricier than other hardwoods.

Maple is moisture-resistant and frequently displays stand-out swirls in the wood grain, an aesthetically pleasing differentiator from other hardwoods.

[10] When the workability of wood is high, it offers a lower resistance when cutting and has a diminished blunting effect on tools.

[10] While many woods can be used for carving, there are some clear favorites, including aspen, basswood, butternut, black walnut, and oak.

[18] Butternut has a deeper hue than basswood and aspen and has a nice grain that is easy to carve, and thus friendly for beginners.

[18] While more expensive than basswood, aspen, and butternut, black walnut is a popular choice for its rich color and grain.