Yarrow boiler

[4] These first boilers, such as the Belleville and Niclausse, were large-tube designs, with simple straight tubes of around 4" diameter, at a shallow angle to the horizontal.

These used smaller water-tubes of around 2" diameter, giving a greater ratio of heating area to volume (and weight).

His conclusion was thus that straight water-tubes were acceptable, and had obvious advantages for manufacture and cleaning in service.

When heat was also applied to the unheated arm, conventional theory predicted that the circulatory flow would slow or stop completely.

Yarrow then repeated the experiment, first with the U-tube at a shallow angle to the horizontal, finally with the entire system under pressure.

Flow was entirely within the heated watertubes, upwards within those closest to the furnace and downwards through those in the outer rows of the bank.

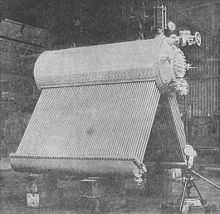

Yarrow's production boiler had a simple and distinctive design that remained broadly unchanged afterwards.

Brick-lined end walls to this casing housed the firedoors or oil burner quarls, but had no heating surface.

The uptake flue from the boiler was in the centre top of the casing, the exhaust gases passing around the steam drum.

To reduce corrosion from flue gases over the drum, it was sometimes wrapped in a simple deflector shroud.

The water level was at around one-third of the steam drum diameter, enough to cover the ends of the submerged water-tubes.

The weight of the boiler rested on the water drums, and thus on supports from the firing flat's deck.

The first Yarrow water drums or "troughs" were D-shaped with a flat tubeplate, so as to provide an easy mounting for the tubes.

Later boilers used a more rounded section, despite the difficulty of inserting and sealing the tube ends when they were no longer perpendicular.

The circulation in a Yarrow boiler depended on a temperature difference between the inner and outer tube rows of a bank, and particularly upon the rates of boiling.

Whilst this is easy to maintain at low powers, a higher pressure Yarrow boiler will tend to have less temperature difference and thus will have less effective circulation.

The design was already well-suited to being fired from both ends and it was discovered that double-ended boilers were slightly more efficient in use.

[10] A secondary effect of the superheater was to increase the temperature differential between inner and outer tubes of the bank, thus encouraging circulation.

This effect was later encouraged in the Admiralty boiler, where the tubes of a bank were curved apart to leave space for a superheater, whilst retaining the single water drum.

The now-asymmetric boiler could pass all of its exhaust gas through the superheated side as the single flow type.

The advantage of placing the superheaters here was that they increased the temperature differential between the inner and outer tubes of the bank, thus encouraging circulation.

[13] The first Yarrow boilers were intended for small destroyers and filled the entire width of the hull.

As for their naval success, they were recognised for having a large radiant heating area and being quick to raise steam.

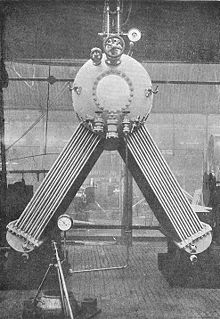

[14] Only one "Yarrow" boiler was used in a railway locomotive, Nigel Gresley's experimental Engine 10000 of 1924 for the LNER company.

[15] Having observed the benefits of higher pressures and compound engines in marine practice, Gresley was keen to experiment with this approach in a railway locomotive.